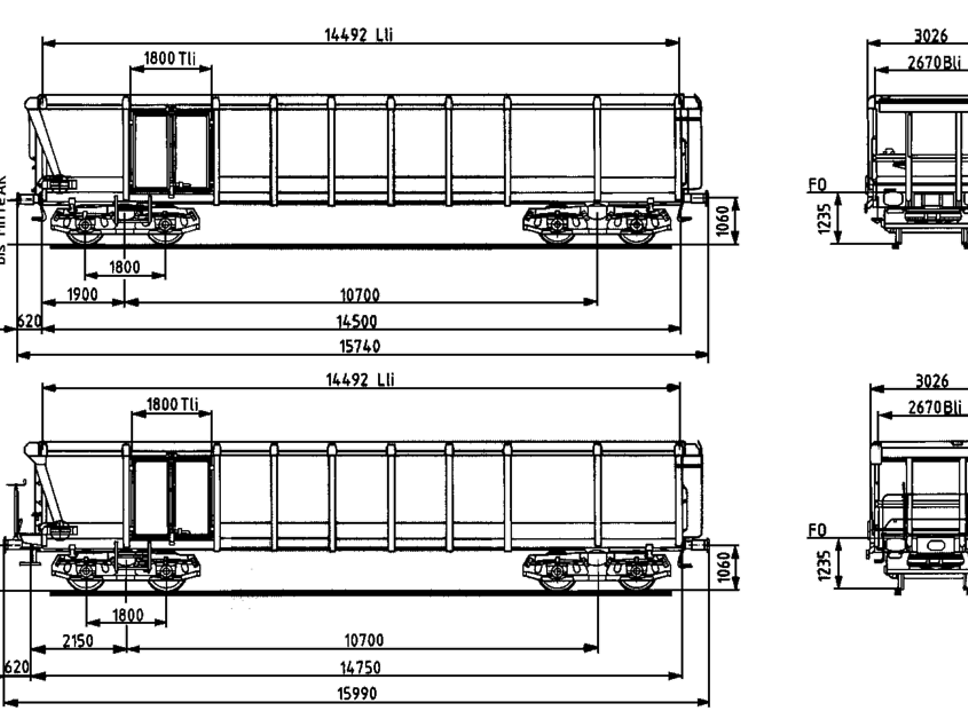

Article: Tamns 893

Wagon with opening roller roof and wide side wall doors, which is particularly suitable for transporting moisture-sensitive bulk goods. Due to its large loading space and low tare weight, it is suitable for loads of different densities.

Type Tamsn-x 893.1 is used for salt transport, and therefore the roller roof has been removed

Technical details

Loading length (mm) | 14,492 |

Loading width (mm) | 2,720 |

Loading height (mm) | 2,040 |

Loading area (m2) | 39.4 |

Loading space (m3) | 80.0 |

Inside width of hopper (mm) | 2,670 |

Inside length of hopper (mm) | 14,492 |

Average tare weight (kg) | 26,000 |

Maximum speed (km/h) | 100 |

International usability | 893.0=yes // 893.1=no |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1987 (prototype), 1988 (series) |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Two-stage, pneumatic, to be changed over manually |

Buffer type | UIC 526-1, Category A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 2adSL-D |

Individual data

Side wall door openings: width (mm) | 1,800 |

Side wall door openings: height (mm) | 1,800 |

Load limits

Tare weight > 25.0 t ≤ 25.5 t

With and without parking brake

A | B | C | D | |

|---|---|---|---|---|

S | 38.0 t | 46.0 t | 56.0 t | 64.0 t |

120 |

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 3.0 | 23.0 | 26.0 |

b-b | 5.0 | 27.0 | 30.0 |

c-c | 10.7 | 39.0 | 64.5 |

d-d | 14.49 | 64.5 | - |

Additional information:

The wagon is particularly suitable for transporting bulk goods that need to be protected from the weather. Due to its large loading space and high payload, it is suitable for products of different densities.

The underframe is a welded structure made from St 37 and St 52 grade steel.

The cladding sheets for the side and end walls are 4 mm thick, while the sheets for the doors are 5 mm thick and made of St 52-3 with added copper. The side wall top chord is continuous and particularly stable due to grab loading and unloading. The floor is made of 6 mm thick sheet metal. Some of the wagons have a floor made of stainless-steel sheets (index letter "x").

The roof is made of a PVC-coated synthetic fabric. Clamping strips are welded to the underside, into which hat-shaped purlins are inserted. The roofing material is not sensitive to weather and is still elastic even at low temperatures.

The roof can be actuated from both sides of the wagon via a hand wheel located near the end wall. Here, a shaft is powered via a speed reducer, which moves two endless roller chains located in the top chord, which have been made of stainless steel from 1992 onwards.

During the opening and closing process, the roof rests on the chains and is therefore not exposed to wear due to friction with the top chord. The roof is locked by means of locks on the hand wheels. A 30 mm square is attached to each of the hand wheels for mechanical drive, which can be provided by electric motors with a maximum of 1,000 W at 160 to 200 rpm. A torque limiter on the hand wheels prevent the drive from being overloaded.