Article: Tds 937

Covered bulk freight wagons with controlled gravity unloading and two wheelsets.

These wagons are suitable for transporting bulk goods that need to be protected from the weather. They are equipped with a trackside discharge device that allows for controlled unloading of the freight. Most vehicles have an interior coating, which is characterised in particular by protection against contamination, more favourable unloading behaviour (slippage) for goods that flow with difficulty and improved corrosion protection for aggressive cargo. Priority cargoes are fertiliser, lime and coke.

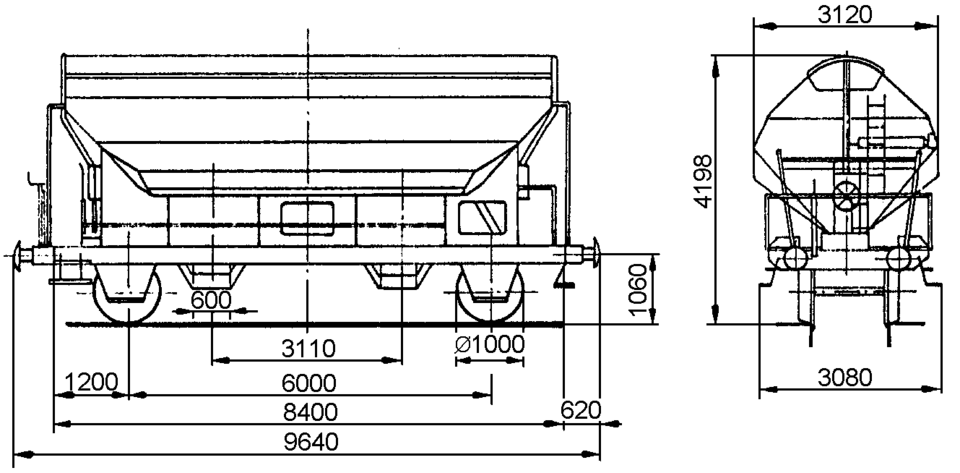

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading space (m3) | 38.0 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 8,000 |

Average tare weight (kg) | 13,500 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1971 |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Two-stage, mechanical |

Buffer type | UIC 526-2 |

Buffer head dimensions (mm) | Avg 450 |

Automatic coupler | Not prepared for installation |

Distributor valve type | KE 1adSL |

Individual data

Type of draw gear | Non-continuous |

Extension spring type | Two conical springs in series |

Minimum tensile force of the extension spring (kN) | 2 x 200 |

Type of spring suspension | Double link |

Width of the swivelling additional chutes (mm) | 600 |

Width of the swivelling discharge chutes (mm) | 600 |

Height of fixed discharge chutes above top of rail, empty (mm) | 700 |

Height of swivelling discharge chutes above top of rail, empty (mm) | 394 |

Clear width of the unloading openings (mm) | 410 x 1,330 |

Distance between centres of the unloading openings (mm) | 3,110 |

Running gear | UIC 517, Annex 4 |

Load limits

Tare weight > 13.0 t ≤ 13.5 t

With and without parking brake

A | B1 | B2 | C | |

|---|---|---|---|---|

S | 18.5 t | 22.5 t | 22.5 t | 26.5 t |

Additional information:

The wagon is intended for transporting all kinds of moisture-sensitive bulk goods, such as salts and fertilisers. The transport of coarse-grained or angular, heavy goods (e.g. gravel, slag, ballast) is not permitted due to possible damage to the inner coating.

The underframe and the wagon body are welded structures using rolled steel sections and sheet metal. Both parts are welded together.

The wagon has two platforms that are accessible from both sides. Both platforms are equipped with a rung ladder. The working platform is equipped with hand levers to operate the sliding gates, with the hand wheel to open the roof and some with a parking brake and emergency brake valve.

The degree of inclination of the hopper-shaped wagon body enables complete self-unloading.

The wagon is unloaded via sliding gates.

The wagon is equipped with a single-shell lifting-swivelling roof. The roof is raised before being swivelled, then swung off to the side, exposing the entire width of the loading opening. When closed, the roof is secured against unintentional shifting.

Moving the freight wagon with the roof open is not permitted.

Cargo residues may only be removed from the loading or unloading lane by lightly knocking on the outer container walls with a rubber hammer or by using air blow lances in the loading space!

For the operation of the wagons, DV 975/2 must be observed.