Article: Taoos-y 894

Covered bulk freight wagons with four wheelsets. The Taoos type freight wagon is intended for transporting moisture-sensitive bulk goods, particularly kaolin, anhydrite, dolomite and aluminium hydroxide as well as fertilisers, salts and other products from the potash mining industry. Loading takes place via a one-part lateral sliding roof. The goods are unloaded in bulk through pyramidal discharge hoppers.

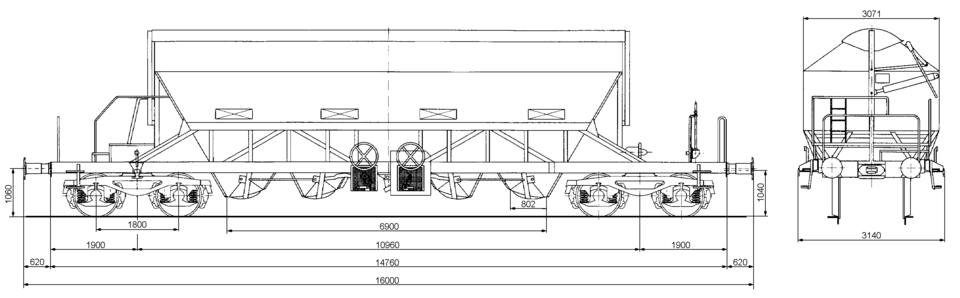

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading space (m3) | 67.0 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 10,120 |

Average tare weight (kg) | 24,500 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1980 |

Conversion year | 1995 (from Uaoos-y 948) |

Parking brake | With parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 2 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Two-stage, pneumatic, to be changed over manually |

Buffer type | UIC 526-1, cat. A |

Buffer head dimensions (mm) | Avg 450 |

Automatic coupler | Prepared (telescopic-leg suspension) |

Distributor valve type | KE 2cSL/c |

Individual data

Width of the unloading openings (mm) | 1,100 |

Length of discharge opening (mm) | 800 |

Number of unloading openings | 4 |

Load limits

Tare weight > 24.0 t ≤ 24.5 t

With parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 39.5 t | 47.5 t | 47.5 t | 55.5 t | |

120 |

Additional information:

The wagon is intended for transporting moisture-sensitive bulk goods, particularly corrosive cargo, such as fertilisers, salt and potash products.

The all-steel wagon body, which is divided into four interconnected chambers and made of low-corrosion sheet metal, and the underframe, which consists of outer solebars and crossbearers, are a welded structure. The compartments are separated in the central area by vertical side walls and partitions as well as end walls inclined at 60° to the horizontal. In the lower part, the limiting surfaces form pyramidal discharge hoppers of the same inclination. Baffles on the butt joints round out the hoppers and make the cargo easier to discharge.

Unloading is done by actuating either of two hand wheels, which are mounted laterally in the centre of the wagon above the solebar. In addition to bulk gravity unloading, the wagon also allows the material in the hopper to be unloaded in a more controlled manner. Loading and unloading generate minimal dust. The design and position of the discharge flaps are primarily responsible for the unloading process not creating much dust. These flaps are brought up to 200 mm above top of rail and can also be adapted to special, stationary extraction equipment.

Cargo residues may only be removed from the loading or unloading lane by lightlyknocking on the outer container walls with a rubber hammer or by using air blow lances in the loading space!

The wagon may only be driven with the roof closed and the swivelling discharge flaps closed.