Article: Shimmns-ttu 728

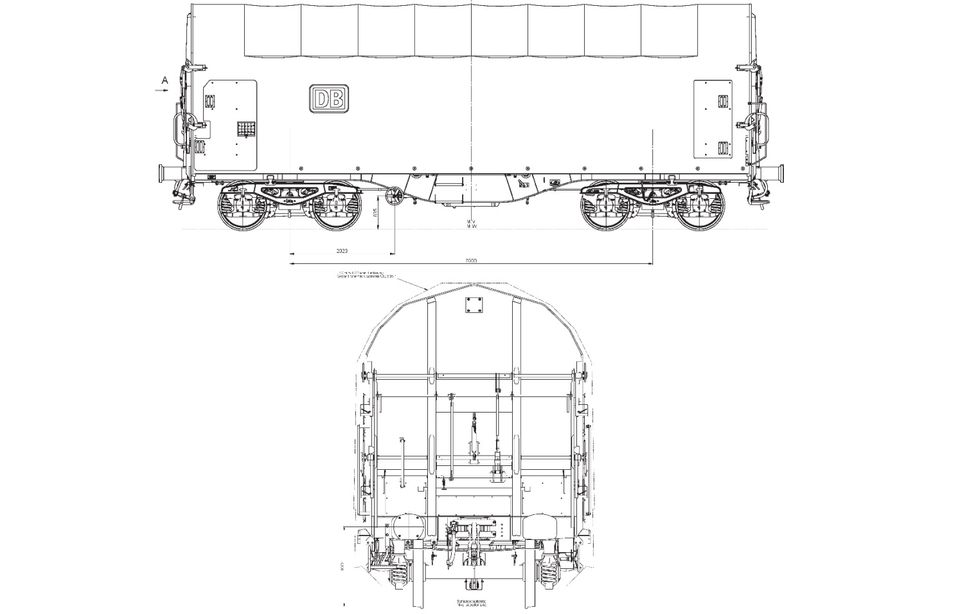

Bogie flat wagon with four wheelsets, sliding tarpaulin cover and loading cradles for coil/slit strip transport.

The five loading cradles and the tarpaulin cover optimise the transport of moisture-sensitive coils. These tarpaulins can each be pushed together so far that two-thirds of the loading area is exposed for loading and unloading.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading width (mm) | 2,052 |

Average tare weight (kg) | 21,500 |

Maximum speed (km/h) | 120 |

International usability | TEN-GE |

Smallest radius of curvature (m) | 35 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A(K) |

Type of load-proportional braking | Stepless, load-dependent, independent, pneumatic |

Distributor valve type | KE2DVSL-ALBD159/1GG |

Load limits

Tare weight ~ 21.5 t

With and without parking brake

A/B1 | B2 | C2 | C3/C4 | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|

S | 38.5 t | 50.5 t | 55.5 t | 58.5 t | 55.5 t | 65.0 t | 68.5 t |

120 | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t |

DB | CM2 | CM3 | CM4 |

|---|---|---|---|

100 | 55.5 t | 62.5 t | 62.5 t |

Additional information:

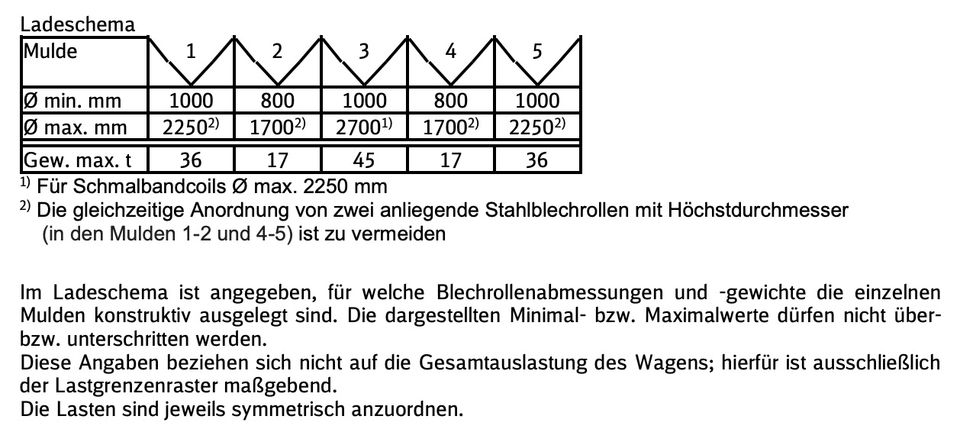

The wagon is especially suitable for transporting heavy sheet metal coils that need to be protected from the weather, which can be safely transported in specially designed cradles.

The wagon has fixed end walls and five loading cradles built into the underframe. The underframe and the end walls, which are a folded frame construction with sheet metal cladding and hat-shaped reinforcement profiles, form the vehicle body. The saddle-shaped cross bearers, each welded to the side solebar, form the loading cradles together with the cradle plates.

The wagon is covered with a PVC-coated fabric tarpaulin, which rests on 11 tubular frames. Two sliding tracks mounted on the side solebar serve as a roller track for several lift-proof carriages, which are connected to the tarpaulin roof via the cross bows and thus make it movable in the longitudinal direction of the wagon.

The tarpaulin roof is locked to the end walls by means of a four-point central locking system that can be operated from a platform or from the ground. Unlocking is possible by only one person from one side of the wagon.

The tarpaulin cover can be pushed open at one end of the wagon to such an extent that approximately two-thirds of the loading area is exposed for loading. To fix the carriages of the tarpaulin cover in the open position, load fastening devices are mounted on the end bow carriages.

The tarpaulin is reinforced between the roof bows so that collapse is reduced by half when pushed together. This creates the necessary clearance for larger coil diameters. The wagon may only be operated with the tarpaulin roof closed and locked.

The wagons are equipped with 20 adjustable holding arms (four per cradle), which are mounted on the cradle humps and supported by rollers in the cradles. Their shape and strength are designed to ensure reliable protection against unacceptable lateral shifts as well as against tilting of tied narrow strip coils. Compared to conventional Shimmns wagons, the holding arms are equipped with a continuous fine adjustment mechanism, which ensures that there is a direct contact to the front surface of the coils, making telescoping impossible.

The lining of the cradles with a 10 mm thick rubber insert is intended to help provide optimum protection of the coil sheet. The rubber support, which is split in the middle, is attached to the saddles of the loading cradles. Between the rubber supports, a white line is applied running lengthwise down the middle as an orientation for the load.

On the top chords of the side solebars there is a walkway made of checker plate to ensure optimum accessibility of the loading cradles. In addition, handles are fitted to the domes of the loading cradles as well as to each holding arm to ensure safe access during loading and unloading.

Foldable transitions made of galvanised light grating are mounted on the bottom of the loading cradles. This allows a safe non-slip transition to the opposite side of the wagon. Under these light gratings there are oil inlets to collect anti-corrosive oil that can run off the coils.