Article: Shimmns-ttu 722

Bogie flat wagon with four wheelsets, sliding tarpaulin cover and loading cradles for coil/slit strip transport.

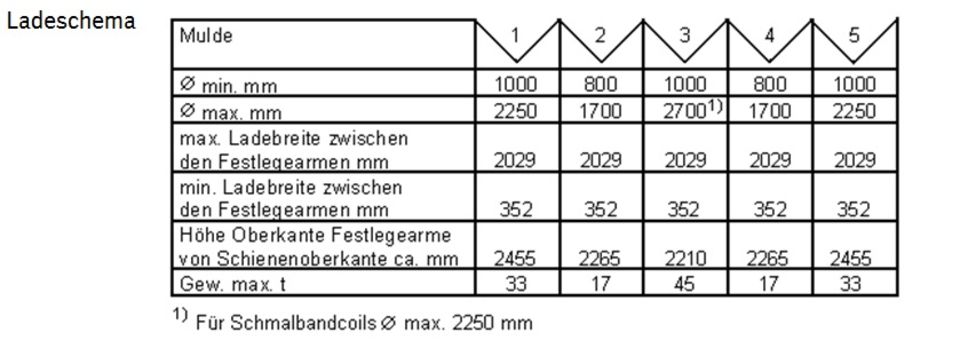

The five loading cradles and the tarpaulin cover optimise the transport of moisture-sensitive coils. These tarpaulins can each be pushed together so far that two-thirds of the loading area is exposed for loading and unloading.

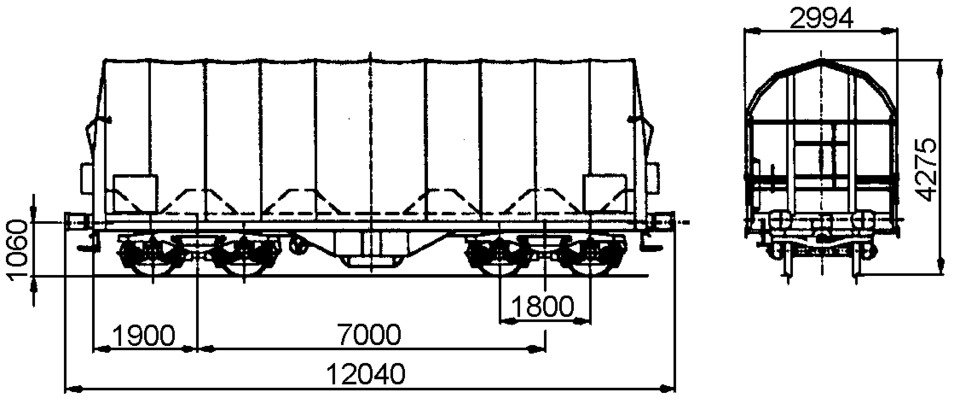

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 10,800 |

Loading width (mm) | 2,400 |

Average tare weight (kg) | 23,500 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC St |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1978 |

Conversion year | 2002 (from Shimmns 708) |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Two-stage, mechanical, to be changed over manually |

Buffer type: end force (kN) | 590 |

Buffer type: stroke (mm) | 105 |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 1adSL |

Load limits

Average tare weight 23.50 t

With and without parking brake

A/B1 | B2 | C2 | C3/C4 | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|

S | 36.5 t | 48.5 t | 53.5 t | 58.5 t | 53.5 t | 63.0 t | 66.0 t |

120 | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t | 00.0 t |

DB | CM2 | CM3/CM4 |

|---|---|---|

100 | 53.5 t | 60.5 t |

Additional information:

The wagon is equipped for transporting heavy sheet metal coils that need to be protected from the weather with five loading cradles permanently installed in the underframe. During the conversion, the steel hoods were replaced by a tarpaulin cover and the end walls and load fastening devices were renewed. The underframe and the end walls, which are a folded frame construction with sheet metal cladding and U-shaped reinforcement profiles, form the vehicle body. The saddle-shaped cross bearers, each welded to the side solebar, form the loading cradles together with the cradle plates. The wagon is covered with a PVC-coated fabric tarpaulin, which rests on 11 tubular frames. The tarpaulin roof can be moved in the longitudinal direction of the wagon by means of carriages. The tarpaulin roof is locked to the end walls by means of a four-point central locking system that can be operated both from the ground and from the ramp. The tarpaulin roof can be pushed together at one end of the wagon to such an extent that approximately two-thirds of the loading area is exposed for loading. Auxiliary bows are arranged between the roof bows in such a way that collapse of the tarpaulin is reduced by half when it is pushed together, in order to ensure the necessary clearance for larger coil diameters. The wagon may only be operated with the tarpaulin roof closed and locked. The wagons are equipped with 20 adjustable holding arms (four per cradle), which are mounted on the cradle humps and supported by rollers in the cradles. Their shape and strength are designed to ensure reliable protection against unacceptable lateral shifts as well as against tilting of tied narrow strip coils.

Compared to the load fastening devices on earlier types (e.g. Shimmns-tu 718), the individual arms can be moved into place, with fine adjustments made using hand wheels. This allows the arms to be brought up to contact with the coils. The lining of the loading cradles with a rubber support is intended to help provide optimum protection of the coil sheet, which is also achieved by a special loading cradle design. Loading instructions and diagrams are displayed on pictograms inside the wagon.