Article: Roos-t 645

Bogie flat wagon with four wheelsets, end walls and stanchions, but without side walls. The wagons have been specially designed for transporting long and heavy cargo – primarily for stem softwood, oak and beech logs and square-sawn timber.

They are equipped with light metal stanchions that can be positioned differently depending on the length of the wood.

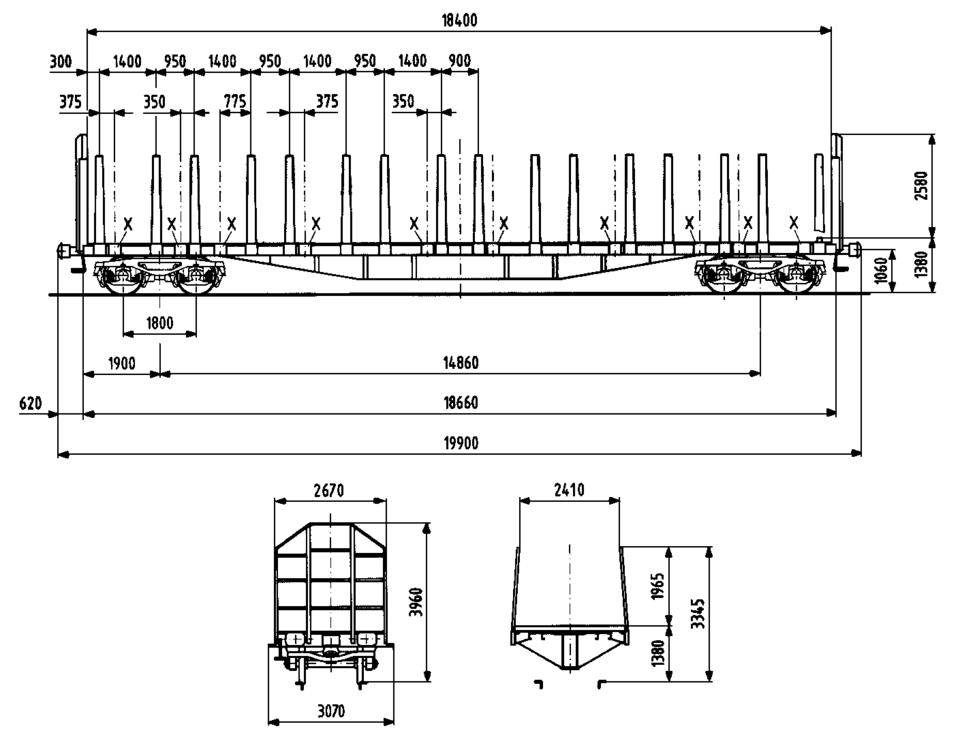

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 18,400 |

Loading width (mm) | 2,650 |

Loading height (mm) | 1,965 |

Loading area (m2) | 48.6 |

Loading space (m3) | 99.0 |

Average tare weight (kg) | 25,000 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1987 |

Conversion year | 2000 (from Res 678) |

Parking brake | Without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | 2-stage, mechanical |

Buffer type | UIC 526-1, cat. A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared (telescopic-leg suspension) |

Distributor valve type | KE 2adSL |

Load limits

Tare weight > 24.5 t ≤ 25.0 t The wagons of this type can have different load limits and concentrated loads due to having different tare weights.

|

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 2 | 32.0 | 33.0 |

b-b | 5 | 35.0 | 38.0 |

c-c | 9 | 36.0 | 44.0 |

d-d | 15 | 44.0 | 55.0 |

e-e | 18 | 55.0 | 24.0 |

Additional information:

The wagon is intended for transporting long and heavy loads, primarily stem softwood (partially barked), oak and beech logs and square-sawn timber.

The high stanchions and high end walls allow logs to be loaded without affixing additional safety devices (interim or indirect fastening) if they are only loaded up to the stanchion height without gaps. Lashing points on the side solebar allow for indirect fastening, e.g. when transporting square-sawn timber packages or long goods (e.g. pipes and rolled products).

The wagon has a walk-through floor. However, it is not possible to drive on the wagon with industrial trucks. The underframe is an all-steel welded structure using sections and folded sheet metal. The continuous main solebars have a fish-belly shape. Each long side of the wagon is equipped with 16 moveable stanchions and ten additional stanchion pockets. The bolsters can be offset for six pairs of stanchions.

There are eight indirect fastening devices on the wagon (tensioning winches with strap, 40 kN nominal breaking force) and lashing rings for securing or covering the load.

All data provided without any guarantee of correctness or completeness.