Article: Rns-z 643

Bogie flat wagon with four wheelsets, drop ends and swivel stanchions, but without side walls. The wagon is used for transporting very semi-finished steel products, long timber and long square-sawn timber.

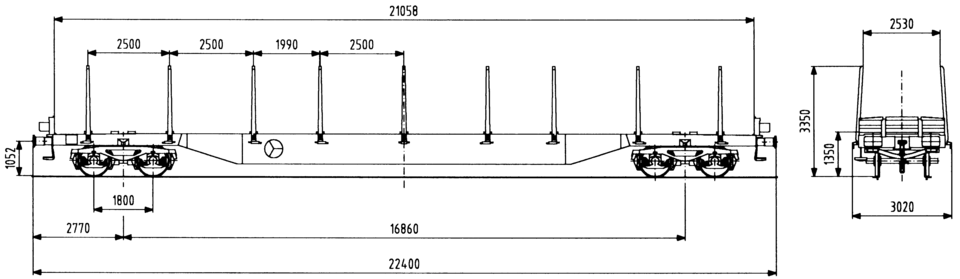

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 21,058 |

Loading width (mm) | 2,710 |

Loading area (m2) | 57.0 |

Average tare weight (kg) | 24,000 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1998 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Automatic |

Buffer type | UIC 526-1, cat. A |

Buffer head dimensions (mm) | 450 x 340 (hardened) |

Automatic coupler | Prepared |

Distributor valve type | KE 2dSL-ALB/d8 |

Individual data

Type of draw gear | Type ZF 1 (Miner) |

Height of bolster above top of floor (mm) | 100 |

Height of bolster above top of rail (mm) | 1,350 |

End wall height above top edge of bolster (mm) | 454 |

Stanchion height above top edge of bolster (mm) | 2,000 |

Load limits

Average tare weight 24.0 t

A | B | C | D | ||

|---|---|---|---|---|---|

S | 40.0 t | 48.0 t | 58.0 t | 66.0 t | |

120 |

DB | CM |

|---|---|

100 | 60.0 t |

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 5.0 | 38.0 | 38.0 |

b-b | 9.0 | 40.0 | 50.0 |

c-c | 14.0 | 48.0 | 60.0 |

d-d | 16.4 | 57.0 | 66.0 |

e-e | 17.4 | 57.0 | 66.0 |

f-f | 19.0 | 66.0 | 34.0 |

Additional information:

The wagon is used for transporting very long mining products, long timber and long square-sawn timber.

The welded underframe, which is made of S355J2G3 grade steel, is pre-bent by 15 mm in the middle of the wagon when empty and sags by 25 mm when loaded.

The wagon floor between the bolsters is made of 3 mm thick checker plate, which can be walked on, but which must not be loaded with cargo or vehicle wheels. Only the bolsters (13 pieces, 200 mm wide, 100 mm high), which can be nailed in the middle and are made of a hardwood-softwood combination, absorb all the vertical forces of the loads.

For transport requirements in which the straightness of the mining products must be ensured after transport, shippers may place up to three auxiliary bolsters between the fixed bolsters. The auxiliary bolsters

- Must not be used for concentrated loads.

- Must be supported on the upper chords of the solebars and must not put any load on the floor plate of the wagon.

- Must be secured against lateral slippage by using the holes in the upper chord with binding wire or plastic tape.

The heavy-duty swivel stanchions (nine pairs) are made of special steels and tilt approximately 90 mm inwards when unloaded. Any permanent deformation of the swivel stanchions caused by improper loading and unloading can only be rectified by replacing the stanchions. The release and fastening (gluing) of the swivel stanchion bolts may only be carried out in specially instructed workshops.

During loading and unloading, the stanchion design requires the usual caution to be exercised. Due to the large leverage of the swivel stanchions relative to the brackets (holding devices for bringing the swivel stanchions into the vertical position), oscillating movements of the cargo to be loaded, which act as ungentle jolts (≥ 5,000 N) at the tip of the swivel stanchion, or other rough actions with the loading equipment, lead to cracking or deformation of the brackets, which subsequently require maintenance in a maintenance facility.

The drop ends are used to secure the load. The wagon can run in a train formation with the drop ends folded down and the end wall stanchions lowered (track curve radius ≥ 150 m).

There are six indirect fastening devices on the wagon (tensioning winches with strap, 40 kN nominal breaking force) and lashing rings for securing or covering the load. The lashing rings on the solebars can be loaded with 60 kN and those on the drop ends with 40 kN.

For tensioning the straps, an operating lever for the winch is located in the middle of the solebar (tensioning winch side).

Some of the wagons are equipped with a parking brake that can be operated from the ground.

All data provided without any guarantee of correctness or completeness.