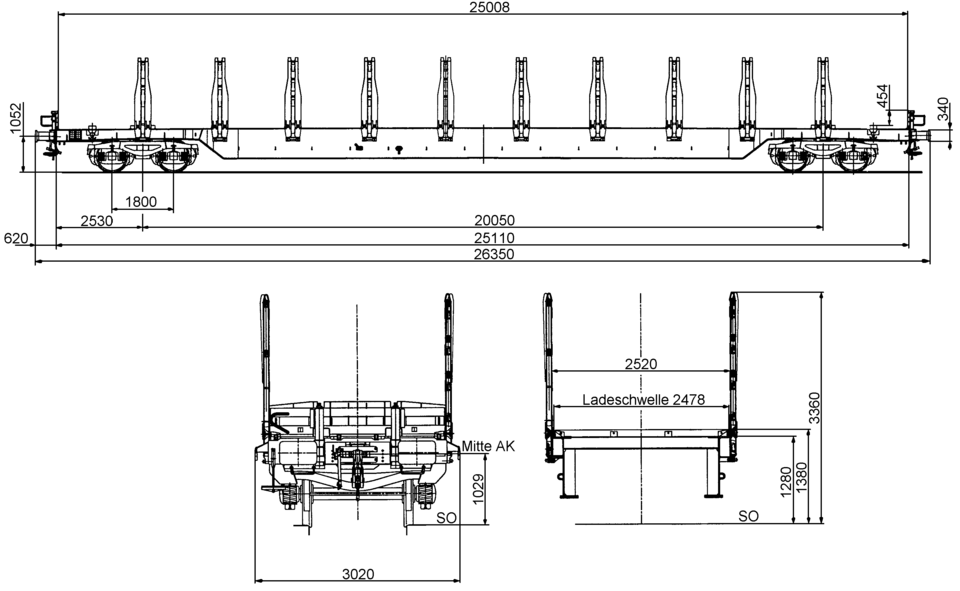

Article: Rbns 646.0

Bogie flat wagon with four wheelsets, with stanchions and drop ends, but without drop sides. The wagon is preferably used for transporting steel products, e.g. pipes and sections.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 25,008 |

Loading width (mm) | 2,520 |

Loading area (m2) | 63.0 |

Average tare weight (kg) | 29,800 |

Maximum speed (km/h) | 120 |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2001 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Automatic, two WM 10 load-proportional valves |

Buffer type | UIC 526-1, Category C (ETH) |

Buffer head dimensions (mm) | 550 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 2dSL-ALB/d8 |

Individual data

Drawing and type of the draw gear | 1Fwg 000.0.05.017.066 (type ST 9-2) |

Stanchion height (mm) | 1,980 |

Load limits

Average tare weight 29.8 t

A | B | C | D | ||

|---|---|---|---|---|---|

S | 34.2 t | 42.2 t | 50.2 t | 60.2 t | |

120 |

DB | CM |

|---|---|

100 | 54.2 t |

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 2.25 | 25.3 | 25.3 |

b-b | 6.75 | 39.5 | 30.8 |

c-c | 11.25 | 42.7 | 35.2 |

d-d | 15.55 | 52.9 | 33.3 |

e-e | 20.05 | 60.2 | 60.2 |

f-f | 23.0 | 60.2 | 31.0 |

Additional information:

The wagon is preferably used for transporting steel products, e.g. pipes and sections. There are bolsters on the wagon floor and stanchions on the long sides of the wagon to hold and support the cargo. Hand-operated indirect fastening equipment is provided to tie down the cargo.

Wooden bolsters are provided in the stanchion area for supporting the load. There is an additional bolster between each of the outer stanchions and the drop ends. The bolsters are high enough to allow the use of standard handling equipment. The bolsters are made of hardwood on the outside with a softwood core, which can be nailed, in the middle.The wagon floor is completely covered with a walk-on checker plate. The covers are not suitable for carrying loads or for driving on with industrial trucks.

Each head end is fitted with a drop end that can be folded outwards to secure the load, which is itself secured by two short stanchions that can be lowered. The wagons can run with the drop ends folded down and the stanchions lowered.

To secure the load, there are ten vertically positioned stanchions at equal intervals on each long side of the wagon. The stanchions are firmly connected to the underframe side solebar and are designed in such a way that they can safely absorb the forces generated by the cargo along the length and the width of the wagon. The connection can be loosened for maintenance (stanchions may only be attached and removed in workshops). The inner sides of the stanchions are lined with a protective strip of laminated wood to protect the cargo.

Each stanchion pair comes with indirect fastening equipment to tie down the cargo; this equipment can be operated by one person. The lashing straps are coated with an elastic material to protect the cargo. The length of the strap and the grid spacing have been chosen such that loads that only occupy about half the height of the stanchions can also be tied down.

All data provided without any guarantee of correctness or completeness.