Article: Kijls 450

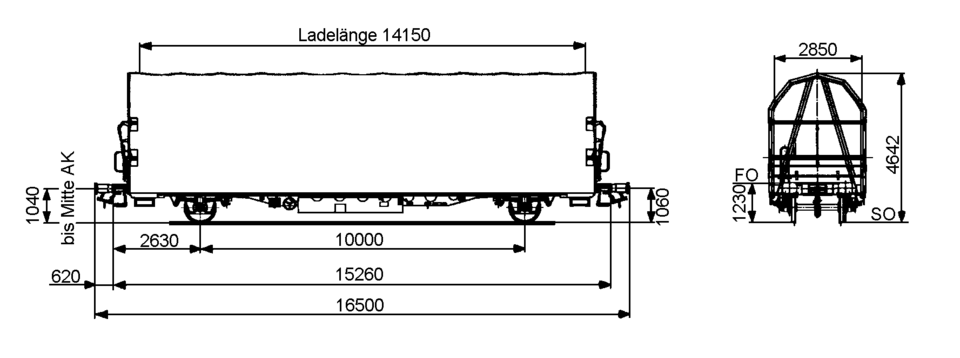

Flat wagon with two wheelsets and opening tarpaulin roof.

A master at bouncing back: with a shock absorber to protect against shunting impacts, this wagon is particularly suitable for transporting goods that are sensitive to shocks.

Due to the closed and locked tarpaulin roof, it also provides protection for moisture-sensitive goods. Additional tensioning systems ensure faster load securing. With a loading length of over 14 m, the wagon offers a loading space of 109 m³.

Technical details

Loading length (mm) | 14,150 |

Loading width (mm) | 2.850 |

Loading area (m2) | 40.3 |

Loading space (m3) | 109.0 |

Average tare weight (kg) | 17,200 |

Maximum speed (km/h) | 120 |

International usability | No |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2001 |

Parking brake | Without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type | UIC 526-1, Category A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE dSL-ALBd63/1 |

Individual data

Running gear as per drawing | 1Fwg450.0.02.000.001 |

Parabolic springs: stretched length (mm) | 1,200 |

Parabolic springs: number of spring leaves | 4 + 1 |

Parabolic springs: spring leaf width (mm) | 120 |

Parabolic springs: spring height (mm) | 202 |

Drawing and type of the draw gear | 1Fwg000.0.05.017.066 (type ST 9-2) |

Load limits

Average tare weight 17.2 t

Without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 14.5 t | 18.5 t | 23.5 t | 27.5 t | |

120 |

DB | CM |

|---|---|

100 | 24.5 t |

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 2 | 20.0 | 22.0 |

b-b | 5 | 22.0 | 24.0 |

c-c | 8 | 25.0 | 27.5 |

d-d | 10 | 27.5 | 27.5 |

e-e | 13 | 27.5 | 10.0 |

Additional information:

The wagon is intended for transporting goods that are sensitive to shocks (e.g. components for the automotive industry, engines, gearboxes, machines, transformers).The wagon has a hydraulic impact beam running underneath the wagon body, which largely protects the goods in the wagon from shunting impacts. This limits the calculated acceleration acting on the load at impact speeds of up to 9 km/h to 1 g (9.81 m/s2).

The end walls consist of two sloping end pillars, two crossbearers and a frame, which also accommodates the sealing system. The metal panelling is 2 mm thick. The robust four-point central locks are located on the end walls and can be used to reliably secure the tarpaulin roof. The actuating devices are positioned in such a way that the tarpaulin roof can be unlocked and locked both from the ground and from a platform. The four locking hooks in total, including the two actuating levers, are connected to each other via shafts mounted on swivel bearings. This makes it possible to actuate the central locking system from either side of the wagon.

The tarpaulin roof consists of two end roof bows and ten middle roof bows with a PVC-coated fabric tarpaulin. The roof bows rest on carriages, which in turn stand on running rails positioned on the solebars. Rollers on the carriages, which grip under the running rails, act as safety devices and prevent the sheets from lifting off in the event of impacts or wind loads.

The tarpaulin roof can be moved to either end of the wagon with little effort and pushed together so much that approx. three-quarters of the loading length is available for unrestricted loading.

All data provided without any guarantee of correctness or completeness.