Article: Hbis-tt 293

Freight wagon with two wheelsets, two-part sliding walls with tarpaulin covering and with a lockable partition.

For delicate loads: this covered freight wagon stands out particularly thanks to its large load volume and a movable and lockable partition, which guarantees optimum securing of loads.

Technical details

Loading width (mm) | 2,590 |

Loading height (mm) | 3,050 |

Loading area (m2) | 33.0 |

Loading space (m3) | 100.5 |

Average tare weight (kg) | 15,500 |

Maximum speed (km/h) | 120 |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1976 |

Conversion year | 1998 (from Hbills-x 295) |

Parking brake | Without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 (double brake cylinder) |

Brake cylinder diameter (mm) | 255/300 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type: end force (kN) | 590 |

Buffer type: stroke (mm) | 105 |

Buffer head dimensions (mm) | Avg 450 |

Automatic coupler | Prepared |

Distributor valve type | KE 2adSL-ALD |

Individual data

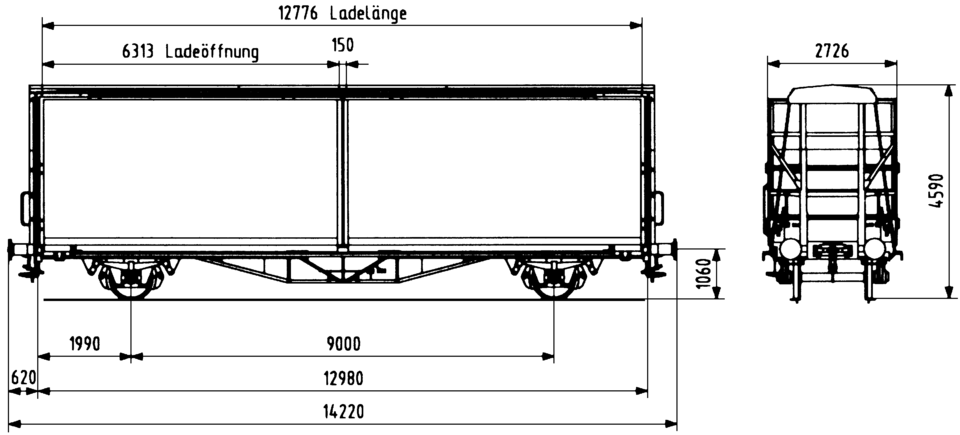

Side wall openings: width (mm) | 6,313 |

Side wall openings: height (mm) | 3,050 |

Running gear as per drawing | 2Fwg295.0.02.000.001 |

Loading length without partitions (mm) | 12,776 |

Loading length with partitions (mm) | 12,660 |

Clearance (mm) | 3,035 |

Load limits

Tare weight > 15,0 t ≤ 15,5 twithout parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 16,5 t | 20,5 t | 20,5 t | 24,5 t | |

120 |

Tare weight > 15,5 t ≤ 16,0 twithout parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 16,0 t | 20,0 t | 20,0 t | 24,0 t | |

120 |

Additional information:

The wagon is a conversion wagon from the Hbills-x 295. It is used for transporting moisture-sensitive goods, in particular automotive parts in stillages.

The wagon is constructed according to reference profile G2 (EBO), but exceeds this reference profile in the exterior roof area. It can therefore only be used on codified routes with profile P/C 400 and larger. An exemption exists for this in accordance with Section 22 of the EBO. Sidings must be checked for clearance before driving over them.

The wagon has a sliding wall system that is guided at the top and runs on rollers at the bottom. During the opening and closing process, the wall is guided parallel to the wagon body. The locking system corresponds to that of the Hbbi(ll)ns 305/306. The actuating devices for the sliding walls are located on the end walls. The sliding walls have a lightweight design and consist of a frame made of steel sections, folded sheet metal and roof bows, as well as a tarpaulin cover.

The underframe and floor have been adopted unchanged from the Hbills-x 295.

To secure the load, the wagon has a lockable partition at one end of the wagon, which can be moved and locked up to 1 m from the end wall.

There are 15 mm high stop bars on the long sides of the floor to centre the cargo. The distance between the stop bars is 2,590 mm.

All data provided without any guarantee of correctness or completeness.