Article: Habbins 354

Freight wagon with four wheelsets and two-part aluminium sliding walls.For delicate loads: these high-capacity wagons are equipped with sliding walls that can be moved by a single person. When open, half of the wagon loading area can be accessed from both sides.

This allows the wagon to be loaded and unloaded using forklift trucks either from a platform or from ground level.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

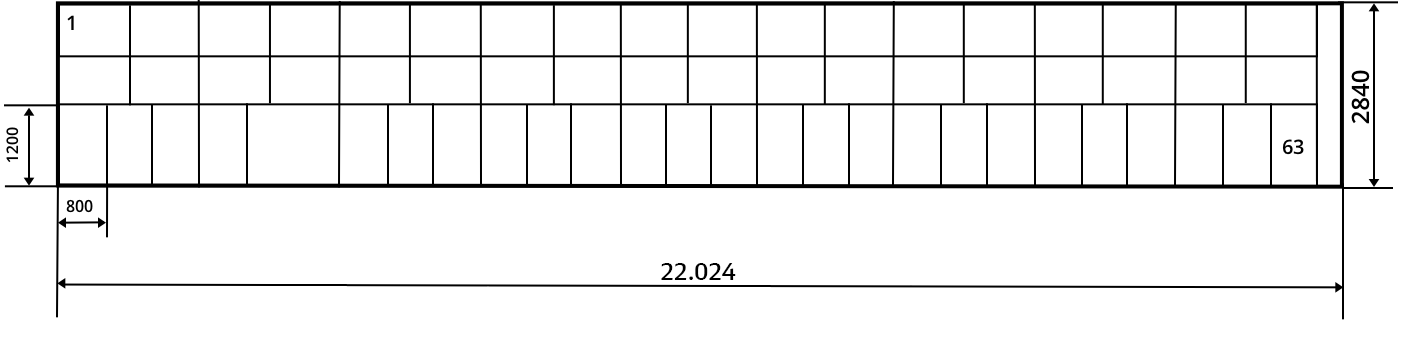

Pallet stowage plan:

Technical details

Loading length (mm) | 22,000 |

Loading width (mm) | 2,840 |

Loading height (mm) | 2,800 |

Loading area (m2) | 62.48 |

Loading space (m3) | 167.4 |

Average tare weight (kg) | 26,500 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1994 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 2 x 16" |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Automatic |

Buffer type | UIC 526-1, Category C |

Buffer head dimensions (mm) | 550 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KERa/3.8-28 KSLn |

Individual data

Side wall openings: width (mm) | 10,813 |

Side wall openings: height (mm) | 2,800 |

Wheelset suspension | Coil springs, UIC 517, Annex C |

Clear ceiling height up to the first slope inward of sliding wall (mm) | 2,101 |

Type and drawing of the bogies | Type 999.7, Y25Ls 22.5t, Poprad 459.9.842.00.01 Msp1 |

Load limits

Average tare weight 26.5 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 37.5 t | 45.5 t | 55.5 t | 63.5 t | |

120 | 00.0 t | 00.0 t | 00.0 t | 00.0 t |

Concentrated loads

m | Spread over the support length | |

|---|---|---|

a-a | 4.0 | 22.0 |

b-b | 7.0 | 25.0 |

c-c | 10.0 | 28.0 |

Additional information:

The wagons are intended for transporting the following moisture-sensitive goods:

- Heavy loads and larger batches.

- Mixed loads of individual pieces of different shapes, weights and sensitivities.

- Goods at risk of tipping, e.g. paper rolls.

- High density goods that can only be stacked to a low height.

The wagon has a sliding wall system that is guided at the top and runs on rollers at the bottom. The sliding wall system allows the wall to be guided parallel to the vehicle body during the entire opening and closing process. The actuating rods for the sliding wall system are located on the end walls.

The underframe is a welded structure and consists of two continuous side solebars and crossbearers that connect the solebars. The floor consists of 30 mm thick plywood boards, the top side of which is coated with an anti-slip material.

The photo shows a type 344 wagon.

All data provided without any guarantee of correctness or completeness.