Article: Habbiins 352

Freight wagon with four wheelsets and two-part aluminium sliding walls.For delicate loads: these high-capacity wagons are equipped with sliding walls that can be moved by a single person. When open, half of the wagon loading area can be accessed from both sides.

This allows the wagon to be loaded and unloaded using forklift trucks either from a platform or from ground level.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

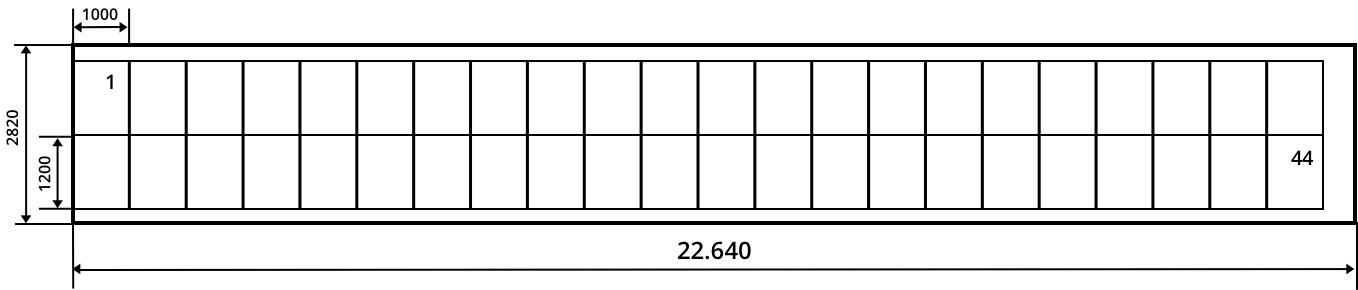

Pallet stowage plan:

Technical details

Loading length (mm) | 22,640 |

Loading width (mm) | 2,810 |

Loading height (mm) | 2,800 |

Loading area (m2) | 63.8 |

Loading space (m3) | 170.0 |

Average tare weight (kg) | 27,400 |

Maximum speed (km/h) | 120 |

International usability | TEN RIV |

Smallest radius of curvature (m) | 60 |

First year of delivery or year of construction of the oldest wagons at this time | 2010 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A (K) |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Automatic, two WM 10 load-proportional valves |

Buffer type | Category A, 40 kJ (3Fwg000.06.004.210) |

Buffer head dimensions (mm) | 550 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE2dvSL-ALB/d72/1 |

Individual data

Side wall openings: width (mm) | 11,140 |

Side wall openings: height (mm) | 2,800 |

Drawing and type of the draw gear | 1Fwg 352.0.05.017.001 (type ST 9-2/170 G) |

Load limits

Average tare weight 27.4 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 36.5 t | 44.5 t | 54.5 t | 62.5 t | |

120 |

Additional information:

The wagon is fitted out as a spacious multi-purpose vehicle with two-part sliding walls. This makes it particularly economical to use for side loading and unloading with industrial trucks. The two sliding walls each expose approx. 50% of the loading length on each side of the wagon. The wagon has been specially designed for transporting rolls of paper, cellulose, square-sawn timber, wooden panels, fibre boards and palletised goods.

The wagon has a sliding wall system that is guided at the top and runs on rollers at the bottom. During the opening and closing process, the wall is guided parallel to the wagon body. The actuating devices for the sliding walls are located on the end walls. Compared to the predecessor types, the actuation is performed transverse to the longitudinal axis of the wagon. The sliding walls are secured against inadvertent shifting in both end positions when open.

The underframe consists of solebars, headstocks and four closed boxes connecting the two solebars. In the head area, the floor is made from a checker plate. Outside this area, the floor is made of 35 mm thick plywood. Lashing points for securing loads are positioned in the wagon floor over the entire length of the wagon, starting approx. 500 mm from the end walls, at intervals of 1,200 mm.

There are two lashing points on both sides of the end walls at a height of 1,200 mm and 1,800 mm from the wagon floor. The body structure is formed by the two end walls, the roof and two central pillars. All wagons have been prepared to accommodate four lockable partitions.

All data provided without any guarantee of correctness or completeness.