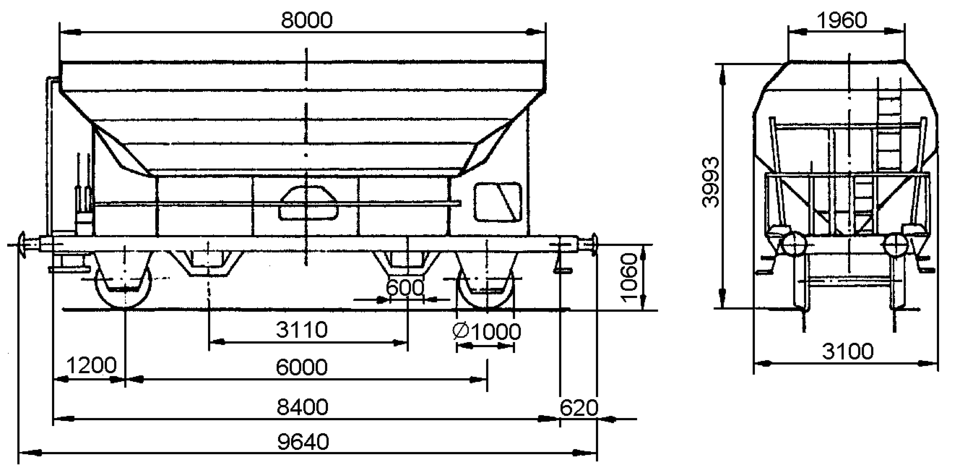

Article: Fcs 088

Open bulk freight wagons with controlled gravity unloading and two wheelsets.The loading space of open self-discharging wagons resembles two hoppers next to one another. The wagons have several discharge openings each equipped with a rotary valve that enable the complete unloading of the wagon contents on either side of the wagon. The wagons are suitable for transporting bulk goods that do not need to be kept dry. The rotary valves can be operated individually using a device on the platform at one end face of the wagon.

Technical details

Loading space (m3) | 40.0 |

Inside width of hopper (mm) | 1,960 |

Inside length of hopper (mm) | 8,000 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1971 |

Parking brake | With parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Two-stage, mechanical |

Buffer type | UIC 526-2 |

Automatic coupler | Statically prepared (telescopic-leg suspension) |

Distributor valve type | KE 1adSL |

Individual data

Type of spring suspension | Double link |

Opening width of the fixed discharge chutes (mm) | 600 |

Width of the wagon body with discharge flaps open (mm) | 3,100 |

Running gear | 088.0.02.000.001 |

Load limits

Average tare weight < 13.0 t

With parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 19.0 t | 23.0 t | 23.0 t | 27.0 t |

Average tare weight < 12.5 t

Without parking brake

A | B1 | B2 | C | |

|---|---|---|---|---|

S | 19.5 t | 23.5 t | 23.5 t | 27.5 t |

Additional information:

The wagon is intended for transporting bulk goods that do not need to be kept dry, such as lignite, lignite briquettes, blast furnace coke, bituminous coal and other products.The wagon body, whose loading space resembles two hoppers next to each other, is completely welded. Each long side of the wagon has two sliding gates, which can be opened and closed individually from the front operating platform. The sliding gates can be locked in various open positions and in the closed position by means of pawl locks.The wagon can be loaded using above-ground bunker facilities and conveyor belts. The wagon is unloaded through sliding gates and extension chutes.

The wagon must not be moved when the extension chutes are opened out.Cargo residues may only be removed from the loading or unloading lanes by lightly knocking on the outer container walls with a rubber hammer or by using air blow lances in the loading space.For the operation of the wagons, DV 975/2 must be observed.

All data provided without any guarantee of correctness or completeness.