Article: Facs 124

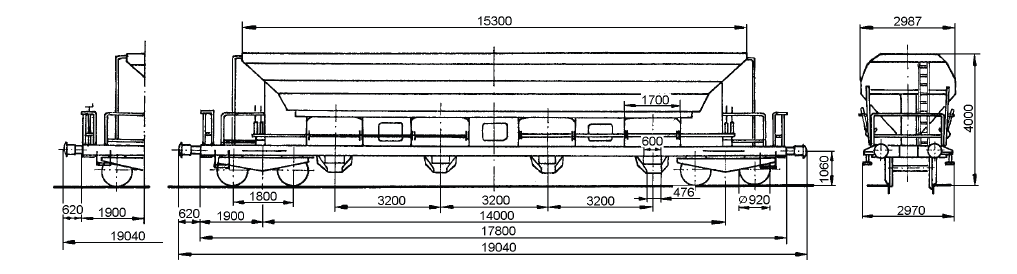

Open bulk freight wagons with controlled gravity unloading and four wheelsets.Nothing left over: the loading space of open self-discharging wagons resembles a series of hoppers. The cargo is unloaded by gravity.The wagons have several discharge openings each equipped with a rotary valve that enable the complete unloading of the wagon contents on either side of the wagon. The discharge rate is controllable, which is often required when unloading the goods onto a conveyor belt. The wagons are suitable for transporting bulk goods that do not need to be kept dry. The rotary valves can be operated individually using a device on the platform at one end face of the wagon.

Technical details

Loading space (m3) | 70.0 |

Inside width of hopper (mm) | 1,800 |

Inside length of hopper (mm) | 15,300 |

Average tare weight (kg) | 25,000 |

Maximum speed (km/h) | 100 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1978 |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Two-stage, mechanical |

Buffer type | UIC 526-1, Category A |

Automatic coupler | Statically prepared (telescopic-leg suspension) |

Distributor valve type | KE 1adSL |

Individual data

Extension spring type | Rubber leaf spring |

Width of the wagon body with discharge flaps open (mm) | 3,070 |

Width of the fixed discharge chutes (mm) | 600 |

Width of the swivelling discharge chutes (mm) | 476 |

Load limits

Tare weight > 24.5 t ≤ 25.0 t

With and without parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 39.0 t | 47.0 t | 47.0 t | 55.0 t | |

120 |

Additional information:

The wagon is intended for transporting bulk goods that do not need to be kept dry.The underframe consists of sheet metal and rolled steel sections welded together. The wagon body is a welded structure and consists of four hoppers. Transverse ribs divide the wagon body into four compartments, each of which has two unloading openings on its lower part, located on either side of the horizontal centre line of the wagon. A support for a vibrator is screwed to the body plate above each unloading opening.

The eight circular sliding gates are mounted on rollers and move on raceways that are attached outside the chutes. A fixed discharge chute and a swivelling discharge chute are positioned under each unloading opening. The swivelling discharge chutes are actuated individually by a lever located near the chute. The sliding gates are actuated from the operating platform.

Once the gates have been opened, gravity acts on the cargo to unload the wagon. Two steps with gratings (500 x 160 mm) are provided for accessing the operating platform.Cargo residues may only be removed from the loading or unloading lane by lightlyknocking on the outer container walls with a rubber hammer or byusing air blow lances in the loading space! For the operation of the wagons, DV 975/2 must be observed.

All data provided without any guarantee of correctness or completeness.