Article: Sgns 696

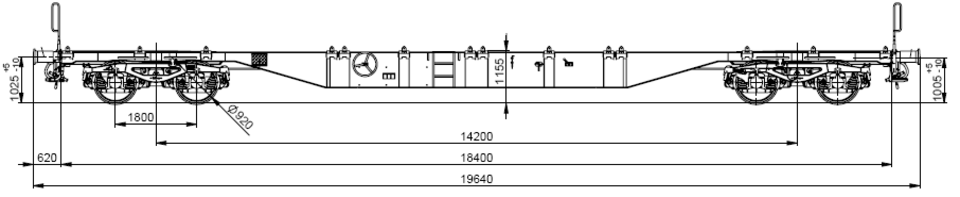

Container wagon with four wheelsets for large containers and jumbo swap bodies.

The wagon features the new container wagon design and is intended for transporting containers on trains used in combined full-container-load transport. The side solebars of the wagon have fixed and folding spigots for fixing the load units in various combinations for each intended loading position.

Technical details

Loading length (mm) | 18,400 |

Average tare weight (kg) | 18,700 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2008 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A (K) |

Number of brake cylinders (pcs.) | 2 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type: end force (kN) | 700 |

Buffer type: stroke (mm) | 105 |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE0DKSLN-6''D |

Individual data

Wheelset suspension | Coil springs according to UIC 517, Annex C |

Height of loading deck above top of rail (mm) | 1,155 |

Loading variants: swap body and container lengths | 3 x 20'; 2*20' - 26'; 1*20' + 1*30'; 2*30'; 1*20' + 1*40'; 1*40' - 45' |

Load limits

Average tare weight

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 45.0 | 53.0 t | 63.0 t | 71.0 t | |

120 |

Additional information:

The wagon features the new container wagon design and is intended for transporting containers on trains used in combined full-container-load transport.The side solebars of the wagon have fixed and folding spigots for fixing the load units (in accordance with UIC Leaflet 592-1 and 2) in various combinations for each intended loading position.The underframe is a torsionally flexible, welded frame construction made of rolled steel and sheet metal sections, formed by the headstocks, the pivot bolsters and the outer solebars.

All data provided without any guarantee of correctness or completeness.