Article: Sgns 691

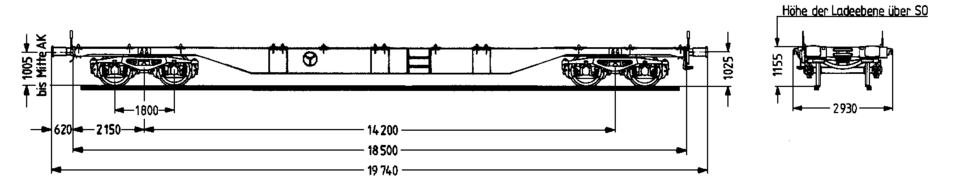

Container wagon with four wheelsets for large containers and jumbo swap bodies.

The wagon features the new container wagon design and is intended for transporting containers on trains used in combined full-container-load transport. The side solebars of the wagon have fixed and folding spigots for fixing the load units in various combinations for each intended loading position.

Technical details

Loading length (mm) | 18,400 |

Average tare weight (kg) | 20,000 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2012 |

Conversion year | 1996 (conversion from Sgns 691.0) |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 2 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type: end force (kN) | 590 |

Buffer type: stroke (mm) | 105 |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 2c AL 2 SL |

Individual data

Height of loading deck above top of rail (mm) | 1,155 |

Ferry ramp angle | 2° |

Loading variants: swap body and container lengths | 3 x 20'; 2*20' - 26'; 1*20' + 1*30'; 2*30'; 1*20' + 1*40'; 1*40' - 45' |

Load limits

Tare weight > 19.5 t ≤ 20.0 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 44.0 t | 52.0 t | 62.0 t | 70.0 t | |

120 |

Additional information:

The wagon is used to transport large containers and swap bodies.

Load units can be loaded in various combinations.

Folding spigots are provided to secure the large containers and swap bodies.

The underframe is a welded structure and consists of two side solebars with a fish-belly shape that are connected by headstocks, pivot bolsters and cross braces.

There are 28 folding spigots mounted on the side solebars. The spigots are made of high-strength cast steel to accommodate the stresses that occur during shunting impacts.

The wagon is equipped with a non-continuous draw gear consisting of a screw coupler, coupling hook with eyelet and draw gear type ST-9-2/160G. The buffer heads are not rotatable.

A left end step, a fold-down spring handle, two signal supports and shunter's handrails are fitted to each end of the wagon.

The wagon has a block brake with stepless, independent load-proportional braking. The braking force is controlled separately for each bogie. Except for the WM 10 load-proportional valves, which are located in the bogies, all pneumatic components, such as the distributor valve, relay valve and brake cylinder, are located in the underframe. Some wagons are equipped with a sheet metal cover as a loading deck.

All data provided without any guarantee of correctness or completeness.