Article: Tamns 895

Wagon with opening roller roof and wide side wall doors, which is particularly suitable for transporting moisture-sensitive bulk goods. Due to its large loading space and low tare weight, it is suitable for loads of different densities.

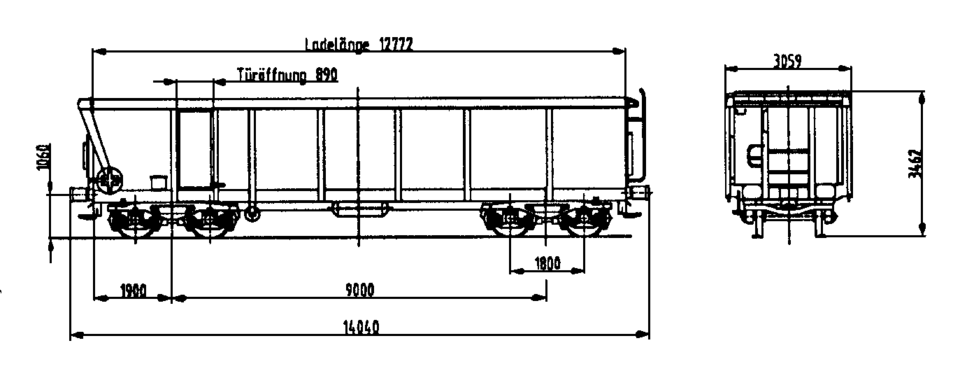

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 12,772 |

Loading width (mm) | 2,780 |

Loading height (mm) | 2,124 |

Loading area (m2) | 35.5 |

Loading space (m3) | 75.4 |

Inside width of hopper (mm) | 2,630 |

Average tare weight (kg) | 20,500 |

Maximum speed (km/h) | 120 |

International usability | Partly RIV |

Smallest radius of curvature (m) | 60 |

First year of delivery or year of construction of the oldest wagons at this time | 1997 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type | UIC 526-1, Category A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared (crossbeam and sliding cradle suspension) |

Distributor valve type | KE 2dSL-ALB/d8 |

Individual data

Side wall door openings: width (mm) | 890 |

Side wall door openings: height (mm) | 1,800 |

Load limits

Tare weight > 20.5 t ≤ 21.0 t

With and without parking brake

A | B1 | B2 | C | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|

S | 43.0 t | 49.0 t | 51.0 t | 61.0 t | 68.5 t | 69.0 t | 69.0 t |

120 |

DB | CM |

|---|---|

100 | 63.0 t |

Concentrated loads

m | Spread over the support length | On two baseplates | |

|---|---|---|---|

a-a | 3.0 | 23.0 | 26.0 |

b-b | 5.0 | 27.0 | 30.0 |

c-c | 9.0 | 39.0 | 69.0 |

Additional information:

The wagon is used for transporting moisture-sensitive bulk goods. Due to its large loading space and low tare weight, it is suitable for loads of different densities.

The underframe and the wagon body are welded steel structures using sections, welded beams and folded sheet metal. A single-leaf hinged door is integrated in each side wall for accessing the wagon. The wagon has a 6 mm thick steel floor. The continuous side wall top chord is designed to accommodate and guide the plastic roller roof.

The tarpaulin roof is made of a coated synthetic fabric; it is held in place over the wagon body by roof bows. The tarpaulin material is not sensitive to weather, is UV-resistant and is still elastic even at low temperatures. The roof is actuated via a hand wheel near the end wall. Here, a shaft is powered via a speed reducer, which moves two endless toothed belts located in the cantrail. Cams are attached to the toothed belts, which run exactly parallel, and take the roof bows with them during the opening process. The roof is locked by means of locks on the hand wheels.