Article: Talns 972

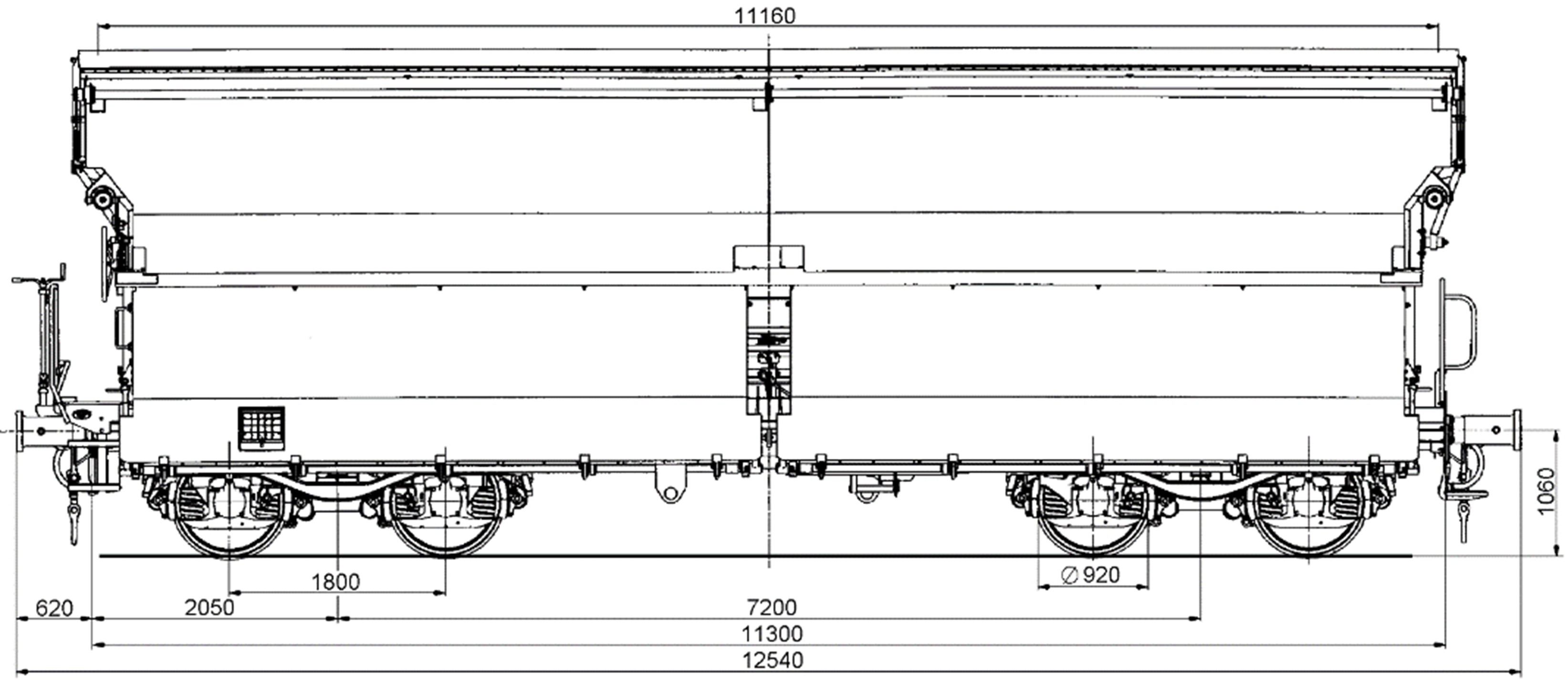

The self-discharging wagon covered with a lateral sliding roof is intended for transporting moisture-sensitive, highly corrosive bulk goods of various kinds. It is particularly suited for unloading into underground bunkers due to four large side flaps in combination with a saddle-shaped floor.

Technical details

| Loading space (m3) | 71.5 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 11,160 |

Average tare weight (kg) | 23,600 |

Maximum speed (km/h) | 120 |

International usability | TEN GE |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2009 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A(K) |

Number of brake cylinders (pcs) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Automatic |

Buffer type:- end force (kN)- stroke (mm) | 590105 |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 2DVSL-ALBD 148/1 |

Individual data

Side flap deflection – largest (mm) | 4,900 |

Side flap deflection – in support position (mm) | 4,100 |

Length of discharge opening (mm) | 5,025 |

Use | Moisture-sensitive bulk goods (salt) |

Wagon category | Talns |

Load limits

A/B1 | B2 | C2 | C3/C4 | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|

S | 38.5 t | 48.0 t | 56.0 t | 58.0 t | 56.0 t | 66.0 t | 66.0 t |

120 |

DB | CM2 | CM3 | CM4 |

|---|---|---|---|

100 | 56.0 t | 60.0 t | 60.0 t |

Additional information:

The wagon body consists of the saddle-shaped floor, the end walls firmly connected to the underframe trusses, the side walls, the four discharge flaps fastened to the side walls and the transverse saddle that divides the wagon body into two equally sized compartments.

The saddle-shaped floor is a truss structure with the lower chords forming the solebars and the top chord or ridge angle below the top of the saddle-shaped floor. Between the solebars are the pivot bolsters, the beams for the air brake system and the supporting structure for mounting the draw gears at both ends of the wagon. The upper part of the wagon body has the shape of a truncated pyramid and is thus also stiffened in the diagonal direction. The material used for the body plates and pads is St 52 Cu.

To load the wagon, the lateral sliding roof is opened from the operating platform with a hand wheel. This exposes an opening with a width of 1,200 mm that extends the entire length of the wagon. The open roof remains within the vehicle gauge.

The side flaps are opened and closed by a mechanical camlock shaft closing mechanism. The flaps are opened in pairs by turning the actuating shaft on the end wall. After opening, the flaps swing freely to the side; the pressure of the cargo falling out determines the size of the deflection.

The flaps are closed individually, outside the bunker area, with a special closing lever.