Article: Tds 925

Covered bulk freight wagons with controlled gravity unloading and two wheelsets.These wagons are suitable for transporting bulk goods that need to be protected from the weather. They are equipped with a trackside discharge device that allows for controlled unloading of the freight. Most vehicles have an interior coating, which is characterised in particular by protection against contamination, more favourable unloading behaviour (slippage) for goods that flow with difficulty and improved corrosion protection for aggressive cargo. Priority cargoes are fertiliser, lime and coke.

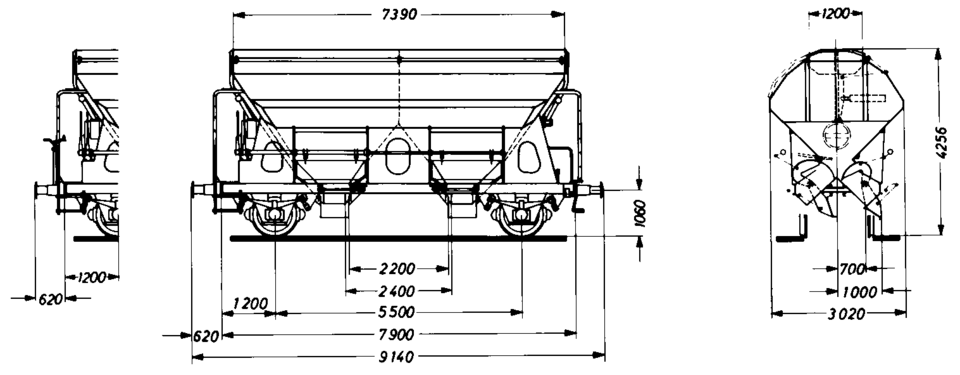

Technical details

Loading space (m3) | 32.0 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 7,390 |

Average tare weight (kg) | 13,000 |

Maximum speed (km/h) | 100 |

International usability | RIV |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1962 |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Two-stage, mechanical, to be changed over manually |

Buffer type: end force (kN) | 350 or 590 |

Buffer type: stroke (mm) | 75 or 105 |

Buffer head dimensions (mm) | Avg 370 |

Automatic coupler | Partly prepared |

Distributor valve type | KE 1adSL |

Individual data

Type of spring suspension | Double link |

Width of the fixed discharge chutes (mm) | 500 |

Width of the swivelling discharge chutes (mm) | 630 |

Running gear as per drawing | Fwg742.02.000.01 |

Load limits

Tare weight > 12.5 t ≤ 13.0 t

With and without parking brake

A | B1 | B2 | C | |

|---|---|---|---|---|

S | 19.0 t | 23.0 t | 23.0 t | 27.0 t |

Additional information:

The wagon is equipped with a lateral sliding roof and has an epoxy resin-based interior paint. It is therefore suitable for transporting all kinds of moisture-sensitive bulk goods with a grain size < 0.5 mm (quartz sand transport). The transport of coarse-grained or angular, heavy goods (e.g. gravel, slag, ballast) is not permitted due to possible damage to the inner coating.The controllable discharge rate enables unloading onto conveyor belts. The swivelling additional discharge chutes allow the wagon to be used for unloading into underground bunkers located directly next to the track. The underframe is welded from rolled steel sections; the wagon body is also welded. St 52-3 steel with added copper has been used for the body plates.The side walls are inclined at 45°, the saddle and end walls at 55° to the horizontal.On each long side of the wagon there are two rotary valves, which can be opened and closed individually from the front operating platform. A pawl lock allows the valves to be opened in 25 mm increments up to 200 mm or to be opened fully at 500 mm. The lower edges of the fixed discharge chutes are 720 mm above top of rail when the wagon is empty; the lower edges of the movable discharge chutes are 415 mm above top of rail when swung out.To load the wagon, the lateral sliding roof is opened from the operating platform with a hand wheel. This exposes an opening of 1,200 mm width extending over the entire length of the wagon. The open roof remains within the vehicle gauge so that shifting movements are possible even when the lateral sliding roof is open.

Cargo residues may only be removed from the loading or unloading lane by lightly knocking on the outer container walls with a rubber hammer or by using air blow lances in the loading space!

For the operation of the wagons, DV 975/2 must be observed.