Article: Tanoos-y 898.3

Covered bulk freight wagons with four wheelsets. The Tanoos type freight wagon is intended for transporting moisture-sensitive bulk goods, particularly fertilisers, salts and other products from the potash mining industry.

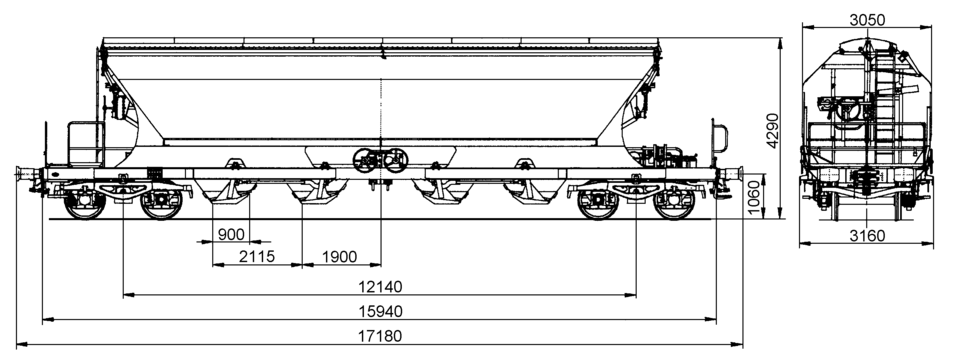

The all-steel wagon body is continuous and only divided between the discharge openings. The goods are discharged through four pyramidal discharge hoppers that are controlled in pairs by two hand wheels. In addition to bulk gravity unloading, the wagon also allows the material in the hopper to be unloaded in a more controlled manner. Loading and unloading generate minimal dust.

Technical details

Loading space (m3) | 90.0 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 12,900 |

Average tare weight (kg) | 24,500 |

Maximum speed (km/h) | 120 |

International usability | TEN GE |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2004 |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 per bogie |

Brake cylinder diameter (mm) | 200 |

Type of load-proportional braking | Automatic |

Buffer type | UIC 526-1, cat. A |

End force (kN) | 590 |

Stroke (mm) | 105 |

Buffer head dimensions (mm) | 450 x 300 |

Reinforced draw gear (kN) | 1500 |

Automatic coupler | Prepared |

Distributor valve type | KE 2dSL-ALB/d111/2 |

Load-proportional valve type | WM 10 |

Year of manufacture | 2010 |

Individual data

Width of the unloading openings (mm) | 1,140 |

Length of discharge opening (mm) | 800 |

Number of unloading openings | 4 |

Height of discharge opening above top of rail (mm) | 410 |

Load limits

Tare weight > 23.5 t ≤ 24.0 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 40 t | 48 t | 58 t | 65.5 t | |

120 |

DB | CM |

|---|---|

100 | 60.0 t |

Additional information:

The central self-discharging wagon equipped with a lateral sliding roof is intended for transporting moisture-sensitive bulk goods with a grain size of >1 mm. The wagon is only suitable for unloading above the track centre line into underground bunkers. Its body comprises a hopper-shaped container that is permanently welded to the wagon's underframe. The wagon features a lateral sliding roof on top and four sliding unloading gates on the bottom. The loading space is continuous and only divided between the discharge openings by three transverse saddles in the lower area. All corners and stiffeners are designed with rounded edges so that almost no load residues can get stuck. The inclined container walls are at an angle of 55° or 60° to the horizontal. To load the wagon, the lateral sliding roof is opened from the operator platform with a hand wheel. This exposes an opening 1,200 mm wide that extends across the entire loading space.

The opened roof remains within the non-restricted kinematic vehicle gauge according to UIC 505-1. In the end position, the roof is secured by the end position lock. The sliding unloading gates are opened and closed in pairs via gearboxes, which are positioned in the centre of the wagon and operated by hand wheel. Unloading can be controlled to a certain extent. This means that the swivelling discharge flaps can be opened and locked in stages, but once an unloading process has been initiated, it cannot be stopped again.

The wagon is an all-steel welded structure using sections, welded beams and folded sheet metal. Primarily S355J2G3 and S355J2G3 Cu grade steel in accordance with EN 10025 is used. The entire loading space, including the swivelling discharge flaps and the lateral sliding roof, is made of corrosion-resistant CrNi steel 1.4301. The wagons are painted with PUR on the outside. The interior surfaces of the loading space are uncoated. All bearing points (except in the bogie) are zero-maintenance and the bearings that are subject to high loads are made of stainless components.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.