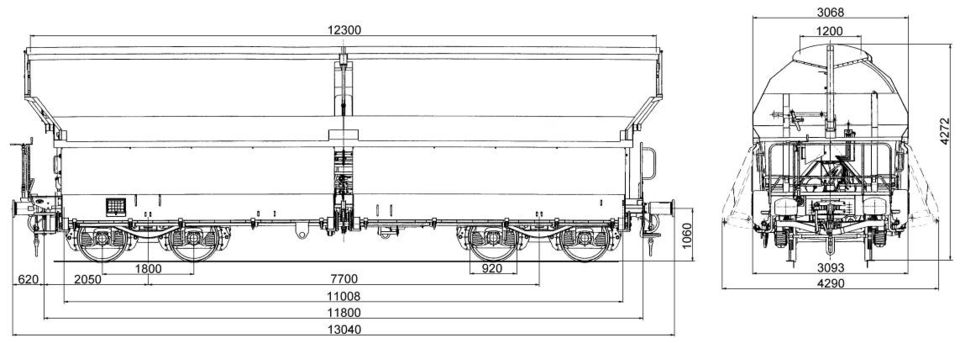

Article: Talns 971

Covered bulk freight wagons with bulk gravity unloading, hydraulic flap-closing system and four wheelsets. These wagons are used for transporting moisture-sensitive bulk goods. Certain wagons have an inner coating to improve flowability.

Technical details

Loading space (m3) | 77.5 |

Inside width of hopper (mm) | 1,200 |

Inside length of hopper (mm) | 12,300 |

Average tare weight (kg) | 25,000 |

Maximum speed (km/h) | 120 |

International usability | TENRIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 2008 |

Parking brake | With parking brake |

Brake type | KE-GP-A (K) |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 300 |

Type of load-proportional braking | Automatic |

Buffer type | UIC 526-1, Category A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE2DVSL-ALBD 125/1 |

Individual data

Side flap deflection – largest (mm) | 4,290 |

Length of discharge opening (mm) | 5,275 (per flap), 11,008 (total) |

Screw coupler, reinforced (kN) | 1,350 |

Draw hook, reinforced (kN) | 1,500 |

Load limits

Tare weight > 24.0 t ≤ 24.5 t

With parking brake

A | B1 | B2 | C | D2 | D3 | D4 | ||

|---|---|---|---|---|---|---|---|---|

S | 39.5 t | 40.5 t | 47.5 t | 55.5 t | 58.5 t | 65.5 t | 65.5 t | |

120 |

DB | CM2 | CM3 | CM4 |

|---|---|---|---|

100 | 58.5 t | 59.5 t | 59.5 t |

Additional information:

The wagon is intended for transporting moisture-sensitive bulk goods of various kinds (e.g. quicklime) to places of unloading equipped with special unloading facilities (underground bunkers). The wagon is to be loaded via above-ground bunkers, hoppers or belt loading systems that ensure central and uniform loading. The wagon has a hydraulic camlock shaft closing mechanism that allows all four flaps to be activated simultaneously (one by four).

The wagon body consists of the saddle-shaped floor, the end walls firmly connected to the underframe trusses, the side walls, the four discharge flaps hinged to the side walls and the transverse saddle that divides the wagon body into two equally sized compartments. The saddle-shaped floor is a truss structure with a segmented design, the lower chords of which form the solebars and the upper chords of which form the ridge under the ridge angle. The saddle angle is 49° to the horizontal. The pivot bolsters, crossbearers, the beams for the air brake system and the drive of the flap-closing system are located between the folded solebars. The contact surfaces where the flaps meet the wagon body and where the roof meets the body, as well as the ridge angles of the longitudinal and transverse saddles, are made of 1.4301 high-grade steel. To prevent cargo residues from sticking, liners are provided in the corners of the body. The upper edge bar at the loading opening has a rounded top and consists of a folded section that forms a closed hollow beam with the upper side wall.

The cargo compartments are closed on each side in the lower area by the flaps. These flaps are suspended in two flap bearings, designed to use self-lubricating Elges spherical plain bearings, on the wagon body. Between these bearing points, the flaps have corrosion-free pressure and support points against the side wall.

The flap is sealed to the pad by means of an overlapping stainless-steel sealing strip. The side seals on the end wall are designed in such a way that rainwater cannot get directly to the cargo. The flap is held in the closed position by five pressure pieces or camlocks on a camlock shaft to achieve a good seal.