Article: Tads(-y) 957

Covered bulk freight wagons with controlled gravity unloading and four wheelsets. These wagons are suitable for transporting bulk goods that need to be protected from the weather. Example cargoes are dolomite, anthracite, gypsum stone, lime, wood pellets, petroleum coke, kaolin and paraffin. Loading takes place via a one-part lateral sliding roof. They are equipped with a trackside discharge device that allows for controlled unloading of the freight.

Technical details

Loading space (m3) | 83.0 |

Inside width of hopper (mm) | 1,200 |

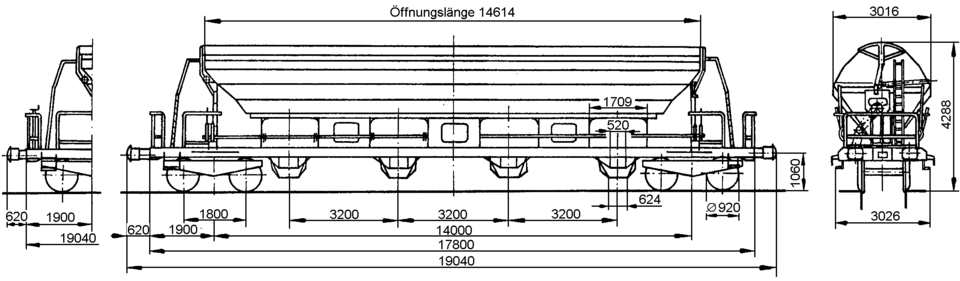

Inside length of hopper (mm) | 14,614 |

Average tare weight (kg) | 27,000 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 75 |

First year of delivery or year of construction of the oldest wagons at this time | 1986 |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Two-stage, mechanical |

Buffer type | UIC 526-1, cat. A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared (telescopic-leg suspension) |

Distributor valve type | KE 1adSL |

Individual data

Type of draw gear | Non-continuous |

Extension spring type | Rubber leaf spring |

Minimum tensile force of the extension spring (kN) | 400 |

Width of the fixed discharge chutes (mm) | 520 |

Width of the swivelling discharge chutes (mm) | 624 |

Height of fixed discharge chutes above top of rail, empty (mm) | 720 |

Height of swivelling discharge chutes above top of rail, empty (mm) | 385 |

Clear width of the unloading openings (mm) | 670 x 1,709 |

Distance between centres of the unloading openings (mm) | 3,200 |

Load limits

Tare weight > 26.5 t ≤ 27.0 t

With and without parking brake

A | B1 | B2 | C | ||

|---|---|---|---|---|---|

S | 37.0 t | 45.0 t | 45.0 t | 53.0 t | |

120 |

Additional information:

The wagons are suitable for transporting all kinds of moisture-sensitive bulk goods, such as salts and fertilisers. Grain sizes < 0.1 mm can be transported without trickle losses. The transport of coarse-grained or angular, heavy goods (e.g. gravel, slag, ballast) is not permitted due to possible damage to the inner coating.The wagon body, sliding gates, chutes and the roof are made of low-corrosion steel. The hopper-shaped wagon body consists of four hoppers and is a welded structure. The hoppers are separated by transverse walls and have openings in the upper part. The end walls are stiffened and connected to the underframe by longitudinal supports.The wagon is emptied simultaneously to both sides of the wagon via eight individually operable sliding gates. The sliding gates are detachable and easy to replace.The wagon is equipped with a single-shell lifting-swivelling roof. The roof is raised by about 60 mm before being swivelled, then swung off to the side, exposing the entire width of the loading opening. When closed, the roof is secured against unintentional shifting. It is not permitted to move the wagon with the roof open.

Cargo residues may only be removed from the loading or unloading lane by lightly _x000B_knocking on the outer container walls with a rubber hammer or by _x000B_using air blow lances in the loading space!

For the operation of the wagons, RIL 975.9570 must be observed.