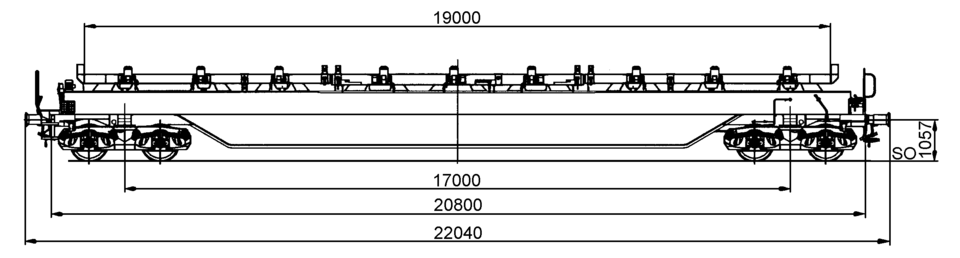

Article: Slps-u 725

Bogie flat wagon with four wheelsets for transporting large sheets.

The Slps-u 725 is a trestle wagon and particularly suitable for transporting large sheets up to a width of 5,500 mm. Due to the inclined position of the loading frames, sheets up to 3,970 mm can be transported without infringing the loading gauge.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 19,000 |

Loading width (mm) | 2,850 to 5,500 |

Average tare weight (kg) | 32,500 |

Maximum speed (km/h) | 100 |

International usability | RIV |

Smallest radius of curvature (m) | 60 | 75 | 90 | 140 |

First year of delivery or year of construction of the oldest wagons at this time | 2001 |

Parking brake | Without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Automatic |

Buffer type | UIC 526-1, Category C |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 2dSL-ALB/d8 |

Individual data

Loading width, adjustable (mm) | 2,850 to 5,500 |

Maximum sheet thickness (mm) | 200 |

Load limits

Average tare weight 32.50 t

Without parking brake

A | B1 | B2 | C | D | DB | CM | |

|---|---|---|---|---|---|---|---|

S | 31.5 t | 39.5 t | 39.5 t | 47.5 t | 57.5 t | 100 | 51.5 t |

Additional information:

This flat wagon type is intended for transporting large sheets, whereby the horizontal position of the hydraulically swivelling loading frame is advantageous for loading and unloading. However, for optimum utilisation of the respective limitations during transport, one of the many adjustable inclined positions can be used.

The fully welded underframe consists of a hollow beam, the two pivot bolsters and the headstocks, which have been prepared for installation of the draw-only automatic coupler. The support brackets for the loading frames are firmly welded to the underframe.

The loading device consists of three loading frames that can be swivelled in increments from 2° to 50° (centre frame up to 60°). Both sides of the loading frame have manually adjustable slide bolts for adjusting the width for loads from 2,850 mm to 5,500 mm in 20 mm increments, which are retained by safety bolts. To secure the load, the ends of all slide bolts are fitted with retaining claws and bolsters are positioned in the middle area. To secure the load, lashing straps with winch and sharp-edge protection are provided on each crossbearer (slide bolt). Short fixed stanchions are provided at the front ends of the outer loading frames to absorb the longitudinal forces. There are also retractable stanchions on the loading frames to absorb the longitudinal forces for short loads (length distribution).

The loading frame can be swivelled to one side with the load by means of an easy-to-operate and reliable hydraulic device. It consists of four differential cylinders equipped with a synchronising device, arranged between the underframe and the loading frame, an electric motor-pump unit with oil reservoir, safety valve and three manual control valves. The loading frames are secured by hydraulic locking valves in all positions and also mechanically secured in the end and intermediate positions. The power supply from the local network is provided by a cable with a five-pin CEE coupling (16 A/380 V) that is not part of the wagon's equipment. It takes approx. five minutes to tilt from 0° to 50°.