Article: Shimmns(-u) 730

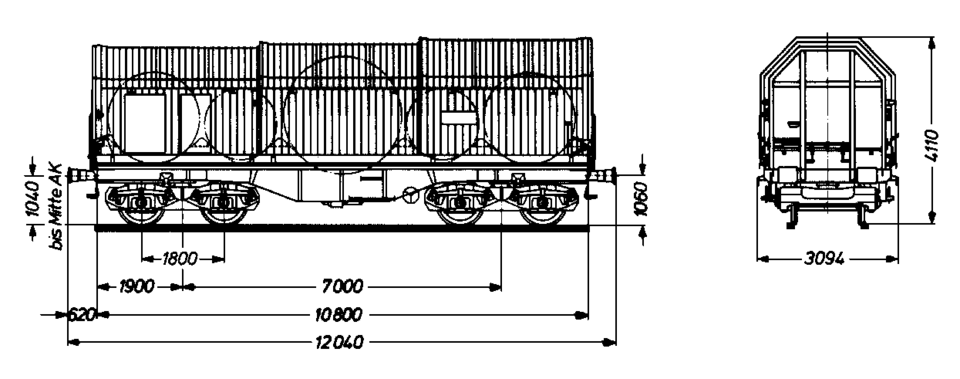

Bogie flat wagon with four wheelsets, sliding tarpaulin cover and loading cradles for coil transport.

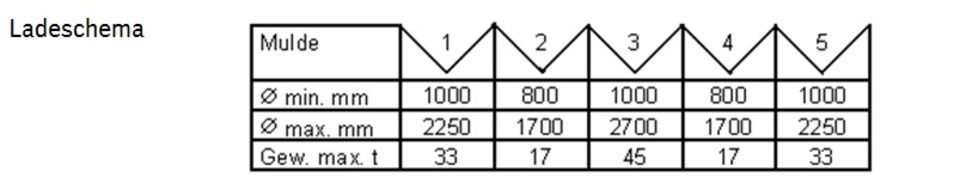

The five loading cradles and the tarpaulin cover optimise the transport of moisture-sensitive coils. These tarpaulins can each be pushed together so far that two-thirds of the loading area is exposed for loading and unloading.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 10,800 |

Loading width (mm) | 2,400 |

Average tare weight (kg) | 22,790 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC St |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1978 |

Conversion year | 1993 (from Shimmns(-u) 708) |

Parking brake | With and without parking brake |

Brake type | KE-GP |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Two-stage, mechanical, to be changed over manually |

Buffer type: end force (kN) | 590 |

Buffer type: stroke (mm) | 105 |

Buffer head dimensions (mm) | 550 x 340 |

Automatic coupler | Prepared |

Distributor valve type | KE 1adSL |

Load limits

Average tare weight 22.79 t

With and without parking brake

A | B1 | B2 | C2 | C3 | C4 | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|---|---|

S | 37.0 t | 37.0 t | 49.0 t | 54.0 t | 59.0 t | 59.0 t | 54.0 t | 63.5 t | 67.0 t |

120 |

DB | CM2 | CM3 | CM4 |

|---|---|---|---|

100 | 54.0 t | 61.0 t | 61.0 t |

Additional information:

The wagon is especially suitable for transporting sheet metal coils that need to be protected from the weather. It has fixed end walls, five loading cradles built into the underframe and three telescopically positioned hoods that can be opened towards both ends of the wagon by sliding them into each other to such an extent that two-thirds of the wagon can be exposed at either end. This allows the wagon to be loaded easily from the top as well as from the side. The wagon may only be operated with the hoods closed and locked.The underframe and the fixed end walls, which are a folded frame construction with sheet metal cladding and hat-shaped reinforcement profiles, along with the three sliding tracks securely positioned on the side solebars on each side of the wagon, form the welded structure of the wagon body. The underframe with its two strong side solebars consists of rolled steel and folded sections. The ends of the underframe consist of the pivot bolsters, the automatic coupler beams and the headstocks.The saddle-shaped crossbearers, each welded to the side solebars, form the loading cradles together with the 6 mm thick cradle plates.The steel hoods, which can slide into each other telescopically, consist of a hollow section frame construction and corrugated metal panelling. The hoods are sealed off from each other and from the end walls by labyrinth-type surround sections. The end hoods lock automatically in the closed position. Unlocking the hoods is possible from the ground as well as from the platform. The locking devices positioned on both sides of each end wall are connected to each other by shafts. This allows unlocking from only one side of the wagon. Each hood runs on four carriages with double rollers mounted on needle roller bearings; each carriage is equipped with lift-off protection.

The wagons are equipped with 12 adjustable holding arms, which are mounted in comb-like brackets fixed to the cradle covers. The holding arms and their arrangement provide effective protection against impermissible lateral movement of the coils. To protect the load, the loading cradles are also equipped with rubber inserts.

In order to exclude impermissible wheel load deviations, the coils must be loaded as centrally as possible. A white stripe running through the centre of all the cradles in the wagon serves as a guide.

The wagons were used in Finnish transport from 1993 until the end of 2003.