Article: Shimmns 729

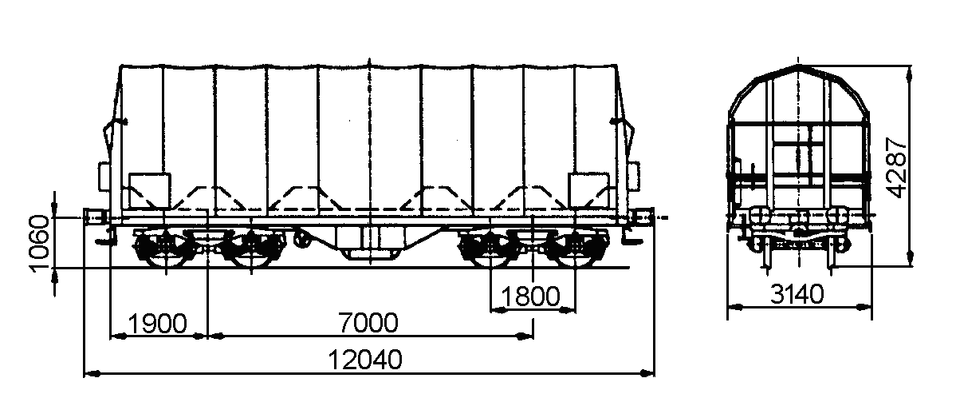

Bogie flat wagon with four wheelsets, sliding tarpaulin cover and loading cradles for coil transport.

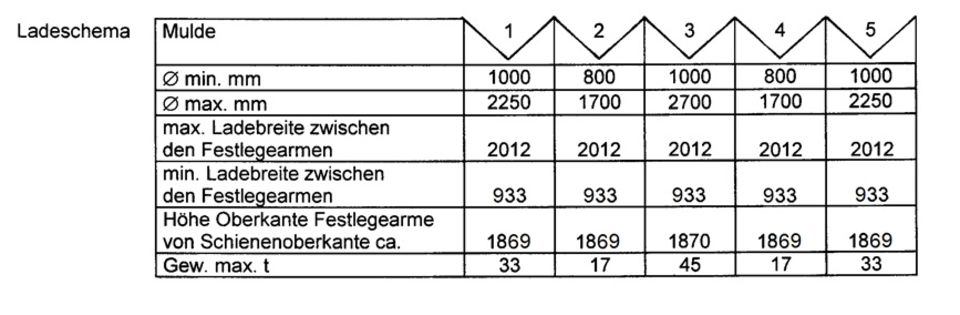

The five loading cradles and the tarpaulin cover optimise the transport of moisture-sensitive coils. These tarpaulins can each be pushed together so far that two-thirds of the loading area is exposed for loading and unloading.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Loading length (mm) | 10,800 |

Loading width (mm) | 2,400 |

Average tare weight (kg) | 22,300 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Harmonisation/standardisation | UIC St |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1996 (taken over from Railion NL/NS Cargo) |

Parking brake | With and without parking brake |

Brake type | Ch-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Stepless, independent, pneumatic |

Buffer type | UIC 526-1, Category C |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared |

Distributor valve type | SAB WABCO/Faiveley: GF4 SA |

Load limits

Average tare weight 22.30 t

With and without parking brake

A | B1 | B2 | C2 | C3 | C4 | D2 | D3 | D4 | |

|---|---|---|---|---|---|---|---|---|---|

S | 37.9 t | 37.9 t | 49.7 t | 54.7 t | 59.7 t | 59.7 t | 54.7 t | 64.3 t | 67.7 t |

Additional information:

The wagon is equipped for transporting heavy sheet metal coils that need to be protected from the weather with five loading cradles permanently installed in the underframe.

The underframe and the end walls, which are a folded frame construction with sheet metal cladding and U-shaped reinforcement profiles, form the vehicle body. The saddle-shaped cross bearers, each welded to the side solebar, form the loading cradles together with the cradle plates.

The wagon is covered with a PVC-coated fabric tarpaulin, which rests on 11 tubular frames. The tarpaulin roof can be moved in the longitudinal direction of the wagon by means of carriages. The tarpaulin roof is locked to the end walls by means of a four-point central locking system that can be operated both from the ground and from the platform. The tarpaulin roof can be pushed together at one end of the wagon to such an extent that approximately two-thirds of the loading area is exposed for loading. The wagon may only be operated with the tarpaulin roof closed and locked.

The wagons are equipped with 12 adjustable holding arms, which are mounted in comb-like brackets fixed to the cradle covers. The holding arms and their arrangement provide effective protection against impermissible lateral movement of the sheet metal coils. The holding arm can be pushed all the way out in the vertical position and locked vertically. A foot pedal must be operated to unlock the holding arms.

The wagons have also been converted from laminated wood inserts to rubber mats in the loading cradles to protect the load. Loading information and instructions are attached to the inside of the end walls.