Article: Rils-y 649

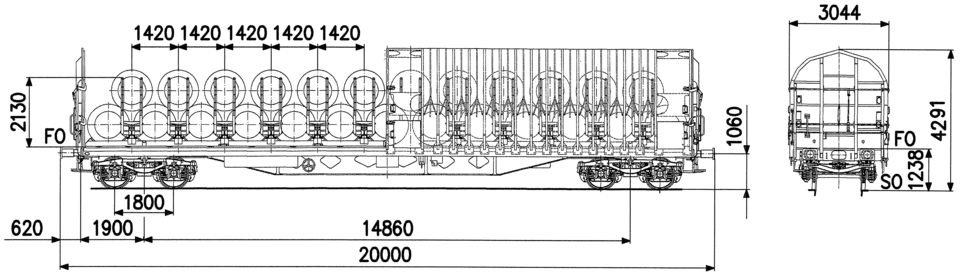

Bogie flat wagon with four wheelsets, with sliding tarpaulin cover and adjustable stanchions.

The freight wagon is equipped with saddle frames specially designed to accommodate wire coils with a maximum width of 2.00 m and a maximum coil diameter of 1.25 m.Each loading frame has 13 wood-lined cradles that accommodate the lowest tier of wire coils. A further 12 coils can then be loaded in the cantlines of the first tier of coils. The load is secured crosswise by 12 pairs of double stanchions that can be positioned by hand.

Please note: Type is similar to the wagon in the photo. For exact dimensions, please refer to the drawing and the data below.

Technical details

Inside width of hopper (mm) | 2.850 |

Inside length of hopper (mm) | 10,102 |

Average tare weight (kg) | > 29,500 ≤ 30,500 |

Maximum speed (km/h) | 120 |

International usability | RIV |

Smallest radius of curvature (m) | 35 |

First year of delivery or year of construction of the oldest wagons at this time | 1993 |

Conversion year | 2004 (from Rilns 654) |

Parking brake | With and without parking brake |

Brake type | KE-GP-A |

Number of brake cylinders (pcs.) | 1 |

Brake cylinder diameter (mm) | 406 |

Type of load-proportional braking | Stepless, independent, pneumatic With 1 load-proportional valve |

Buffer type | UIC 526-1, Category A |

Buffer head dimensions (mm) | 450 x 340 |

Automatic coupler | Prepared (crossbeam and sliding cradle suspension) |

Distributor valve type | KE 2dSL-ALB/d8 or KE 2dSL-ALB/d22 |

Individual data

Maximum cargo width (mm) | 2,000 |

Smallest inner stanchion distance (mm) | 1,600 |

Largest inner stanchion distance (mm) | 2,200 |

Load limits

Tare weight > 29.5 t ≤ 30.0 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 34.0 t | 42.0 t | 52.0 t | 60.0 t | |

120 |

Tare weight > 30.0 t ≤ 30.5 t

With and without parking brake

A | B | C | D | ||

|---|---|---|---|---|---|

S | 33.5 t | 41.5 t | 51.5 t | 59.5 t | |

120 | 00.0 t | 00.0 t | 00.0 t | 00.0 t |

DB | CM |

|---|---|

100 | 54.0 t |

DB | CM |

|---|---|

100 | 53.5 t |

Additional information:

The wagon is intended for transporting wire coils that need to be protected from the weather. In the course of the conversion, a stillage was integrated into the wagon to enable wire coils to be loaded in two tiers.

The stillage consists of 13 wood-lined loading cradles in which the coils can be placed. In the upper position, a maximum of 12 coils can be placed in the saddles of the lower coils, taking into account the load limit according to the load limit panel. For transport, all loading cradles must always be loaded with cargo first before coils are loaded in the upper tier. If the upper tier is not completely filled, the cargo must be evenly distributed over both bogies or in the middle of the wagon.

The lateral stanchions – two stanchions each are mounted together on a guide carriage – can be positioned manually at right angles to the longitudinal axis of the vehicle according to the width of the cargo.

The wagon is covered with a PVC-coated fabric tarpaulin, which rests on 18 tubular frames. The tarpaulin roof can be moved in the longitudinal direction of the wagon by means of carriages. The tarpaulin roof is locked manually in the closed position. The four-point central locking system on the bulkhead is robust and simple. Due to the selected arrangement of the actuating device, the tarpaulin roof can be unlocked both from the ground and from a ramp. The locking hooks arranged on both sides of each end wall, including their operating levers, are connected to each other by a shaft mounted on a swivel bearing. This allows operation from only one side of the wagon. The tarpaulin roof can be pushed together at one end of the wagon to such an extent that approximately two-thirds of the loading area is exposed for loading. Auxiliary bows are arranged between the roof bows in such a way that collapse of the tarpaulin is reduced by half when it is pushed together, in order to ensure the necessary clearance. The wagon may only be operated with the tarpaulin roof closed and locked.The end walls are composed of two outer and two middle end pillars and a frame to hold the rubber seal. The metal panels are made of 3 mm plates.Please note:This type has been undergoing renovation since 2012. Among other things, the stanchion skids will be converted from a sliding plate system to a permanently smooth-running roller bearing system. Stanchion skids with a white dot or wagons that have a white dot in the border field have been renovated. The stanchion skids may only be unlocked and shifted manually. Incorrect operation may result in damage to the self-locking bolt of the stanchion skid. The self-locking bolt on the inside of the wagon must be present and undamaged.

The wagon may only be unloaded with cants up to max. 110 mm; otherwise there is a risk of tipping over. The main reservoir pipe of the box tipper should be connected to the locomotive at least 20 minutes before the destination in order to fill the tipping air reservoirs. The air control system has been designed to ensure the loading cradle cannot tip unintentionally when the tipping air reservoirs are being refilled when the train is running. Filling the reservoirs from 0 to 7.4 bar takes approx. 20 min. No tipping process should be initiated below 7 bar.

All data provided without any guarantee of correctness or completeness.